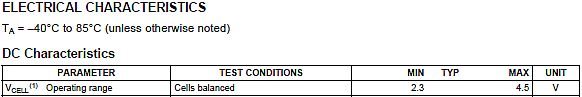

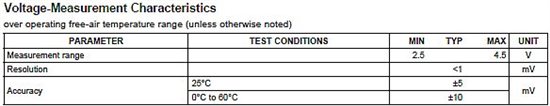

I don't know how may developers at at this stage yet, but, there is a problem with the "114" system and doing UN/DOT testing. We've just got our failed packs back from the lab and during vibration the 78PL114 chip shut discharge FET "OFF" because of "Fuse" flag was set. Yet there were no alarms set. I am assuming that an alarm must have set but then the condition recovered. From the voltage levels of all the packs, I am assuming it was from an Under-voltage condition. I don't see that under-voltage would cause a second level failure resulting in the red "Fuse" status light to show up in the BQ wizard screen, but then I wouldn't know what did. I have tried to erradicate all possible chances for the "Fuse" LED display not to show up during operation of our test units. I have "zeroed" out all possible "threshold times" except those needed for UN/DOT testing such as "Over-Voltage" and "Under-Voltage" and "over-current". I don't know if I got them all, but I still get "Fuse" permanent failures that require me to do a software reset. This is a problem with the UN/DOT testing because any loss in pack voltage is a failure in this $5000 test, end of story. (Not to mention the cost in packs.) I've brought this up before, but, TI should provide a bare-bones "ppscv" file that has the bare minimum protection turned on, like OV, UV, OC and SC. Not everything ON. Randy

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.