Tool/software:

We found this with TLV71333PDBVR.Does this part need soldering?Does the welding standard of this lC and the position of the upright side cut copper require tinning welding

We found this with TLV71333PDBVR.Does this part need soldering?Does the welding standard of this lC and the position of the upright side cut copper require tinning welding

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Hi,

The pin in question is the EN pin. This pin definitely needs to be soldered down. The only pin that would be electrically acceptable to not have soldered is pin 4 NC, but for mechanical stability, all of the corner pins need to be soldered down, so that is to say that all pins need to be soldered.

Regards,

Nick

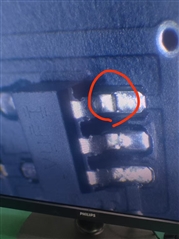

I konw all pins need to be soldered. But my question is: Is the forming process of the five pins TLV71333PDBVR plated first and then formed? Can the vertical surfaces of these five pins on the PCBA not be soldered?Because we see the situation in this picture on the raw materials, it seems that there is copper and it is plated first and then formed. Can this surface not be soldered?

I konw all pins need to be soldered. But my question is: Is the forming process of the five pins TLV71333PDBVR plated first and then formed? Can the vertical surfaces of these five pins on the PCBA not be soldered?Because we see the situation in this picture on the raw materials, it seems that there is copper and it is plated first and then formed. Can this surface not be soldered?

Hi,

My apologies, I was out of office until today.

I believe that the leads are plated first and then formed. I will confirm with our packaging team.

I see your point on the end of the lead that is vertical. The vertical part of the lead does not need to be soldered, but visually confirming a good solder joint is more difficult if it is not.

Regards,

Nick

Hi,

Apologies for the delay.

I heard back from the packaging team. The forming/coating process has a different flow depending on where the devices are assembled - in one case the lead frame is pre-plated, and in the other case, the leads are coated post-form but not post-form. In both cases there will be exposed copper on the "toe" of the lead, but in both cases the toe does not need to be soldered.

I hope this answers your question.

Regards,

Nick