Other Parts Discussed in Thread: BQ40Z50

Tool/software:

Dear TI Team,

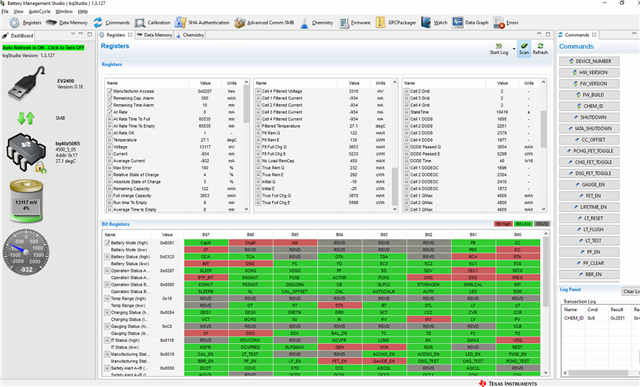

im using a 4s2p battery pack with the BQ40Z50 R2 with the R5 FW.

The Chemistry was provided by the Pack manufacturer: 2851 cell is Panasonic NCA653864SA 2400mAh

I've applied the ChemID, it was programmed successfully.

I properly calibrated the gauge (current, voltages, temperatures), there is no leak current.

I can connect and disconnect the gauge from the system to ensure there is no current flowing to take an OCV.

However, my capacity measured by the gauge is still around 4000mAh insted of 4800mAh that should be the nominal capicity.

Therfore no QMAX update is taken....

My discharge current is usually around 700-900mA at the cycleing.

Did i missed someting?

TIProgData.gg.csv

Many thanks for your support!