Other Parts Discussed in Thread: LM5122, LM5085

I implemented a solution using LM5122 to boost Votlage from 12V to 50V. The solution proposed by WeBench was implemented:

webench.ti.com/.../14

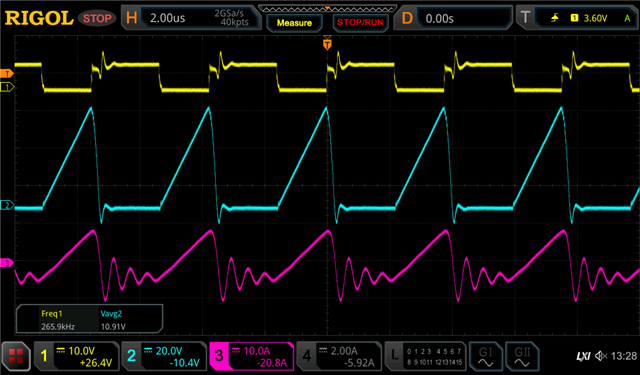

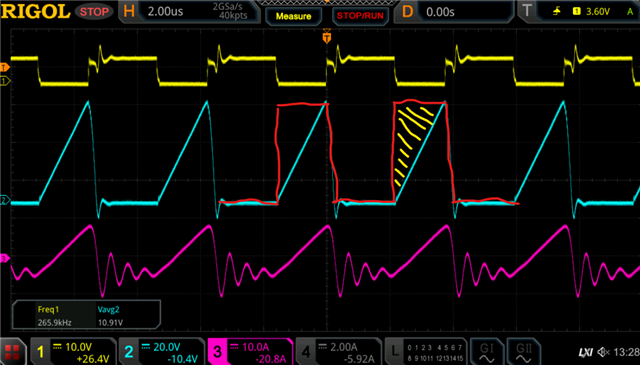

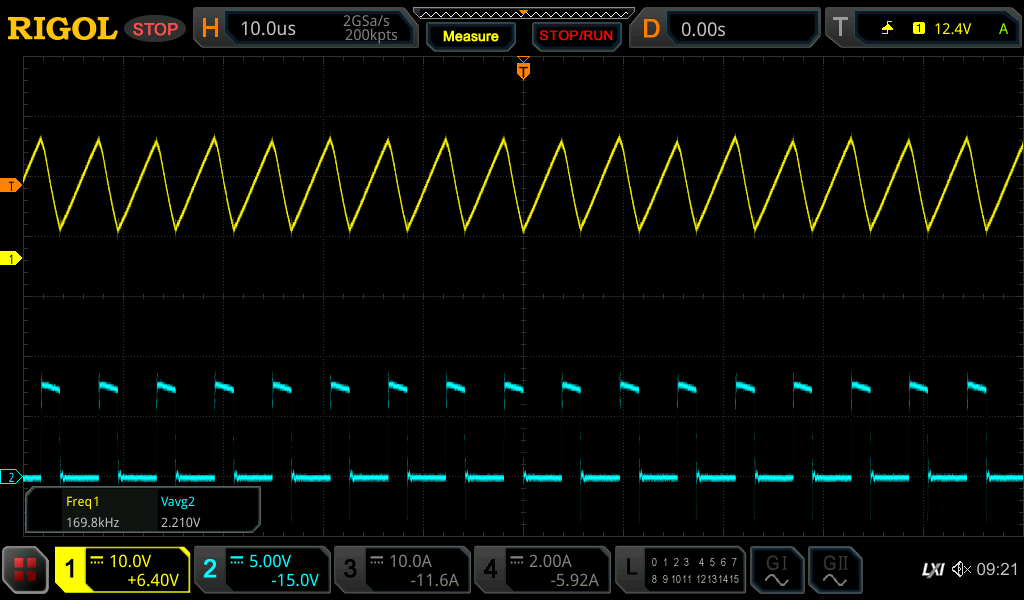

This solution is unstable when boosting to 50V. The data sheet suggests that it might be a problem when the duty cycle is >50% and that the Slope control should be used.

I reduced the boost Voltage and found that it was stable up to around 50% duty which gave only around 20V.

I found some problems with the formulae for calculating the Slope re

sistor. Section 7.3.4 shows a formula for Rslope that includes a constant 'K' and the formula for 'K' includes the value for Rslope, so there's a circular argument and neither can be solved.

sistor. Section 7.3.4 shows a formula for Rslope that includes a constant 'K' and the formula for 'K' includes the value for Rslope, so there's a circular argument and neither can be solved.

After experimenting with Slope resistor values I made some improvements and have increased stability for Voltages up to 30V.

Without a robust method for properly calculating Rslope it will take a long time to resolve.

Also, should the loop compensation components change when the Slope control changes?