Dear Sir,

I am planning to use LP38513-adj regulator for 3.3V and 1.2V. Please recommend the appropriate heat sink model for this regulator to place in the PCB.

Thanks,

V. Prakash

This thread has been locked.

If you have a related question, please click the "Ask a related question" button in the top right corner. The newly created question will be automatically linked to this question.

Dear Sir,

I am planning to use LP38513-adj regulator for 3.3V and 1.2V. Please recommend the appropriate heat sink model for this regulator to place in the PCB.

Thanks,

V. Prakash

You may or may not need a heat sink for your design. The first thing you will want to do is to calculate the power dissipation for your design. Then calculate the junction temperature without a heat sink. If the junction temperature is less than 125deg C, you will not need a heat sink. It it it higher, I suggest using a heat sink. Rather than recommending a heat sink to you in this forum post, I will recommend that you contact your local distributor to assist with that selection. Your distributor will be sure to recommend a heat sink that is part of their line card so they can provide you with the technical support you may need to understand and use the heat sink. Also note that there is a lot of good thermal information at www.ti.com/thermal . The thermal calculator may also be of assistance. http://www.ti.com/adc/docs/midlevel.tsp?contentId=76735 If your sprecific IC is not included in the calculator, you can use an IC with a similar package size. Although the thermal parameters for your specific IC may not match the parameters of the IC in the thermal calculator, they will be close.

Dear Sir,

Can you please let me know the formula to calculate the Heat sink needed for LP38513-adj

Thanks,

V. Prakash

The datasheet contains a paragraph that provides a good amount thermal information, including the equations you are looking for.

I presume that you have read the LP38513-ADJ datasheet section for heatsinking the TO-263 THIN package, and have reached the conclusion that with your required operating conditions it is not possible to dissipate the heat through the package DAP into your printed circuit board.

You may find the following documents helpful:

Understanding Thermal Dissipation and Design of a Heatsink ...

http://www.ti.com/general/docs/lit/getliterature.tsp?literatureNumber=slva462&fileType=pdf

Application Note 2020 Thermal Design By Insight, Not Hindsight...

Dear Sir,

Now i am quite clear about using the Heat Sink. I had designed the board with LP38513TJ-adj for 1.2V. When i load for just 400 mA. the IC is getting Heated

and the IC gets failed. Actually it should support for 3A rating. what may be the cause for this issue. I had designed the single layer board as layout attached.

Please let me know.

Thanks,

V. Prakash

The IC is capable of providing the rated datasheet current as long as you properly take the thermal considerations into account. You must keep the load current less than the rated maximum and the junction temperature less than the rated maximum. What is your power dissipation? Datasheet will give you the equation to calculate power dissipation. It appears that you have isolated the copper where you solder the IC to the PWB. This significantly decreases the power dissipation capabilities of your design. A better design would have continuous copper etch to allow better spreading of the heat from the IC. I think it would be a good idea for you to contact your local distributor FAE so they can go over the basic details of your design and provide local assistance.

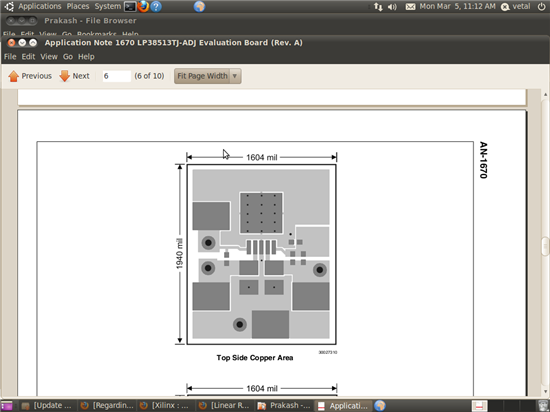

If your pcb is a direct copy of the top-side copper area ONLY then you will have poor thermal performance due to the isolation of the DAP copper area. Single sided copper is not very efficient unless you have large solid area. I would estimate that the thermal resistance, Theta(ja), using the evaluation board pcb layout with the top-side copper area ONLY would be near 60°C/W, which would allow about 1.6W of dissipation with an ambient temperature of 25°C

This layout requires two layer copper, with connections via the 15 thermal vias to the large copper area on the bottom side to achieve the evaluation board thermal resistance rating, Theta(ja), of 35°C/W, which will allow about 3W of dissipation with an ambient temperature of 25°C.

Going to a 4-layer JEDEC type pcb could improve thermal resistance to 20°C/W wihich would allow about 5W of dissipation

Dear Sir,

Thanks for the replies. As you suggest i will go with two layer PCB and check. if i have to take 1.2V/3A means, i have to go for

4 layer PCB or i can go with two layer itself to fill the DAP copper area connected to the other layer of the PCB.

Thanks,

V. Prakash

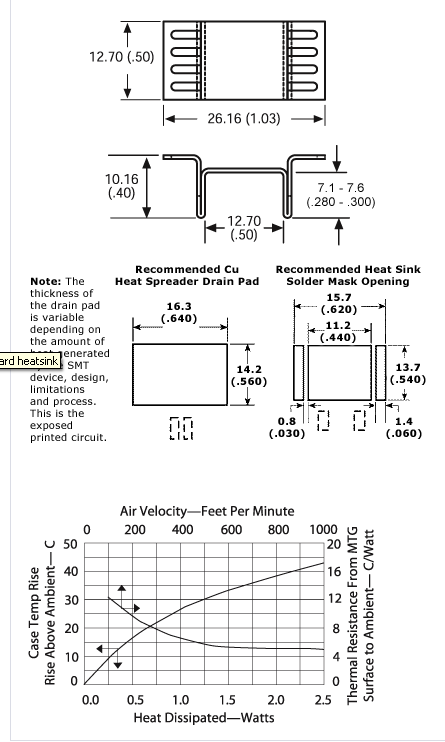

Even though you may not need a heat sink with an improved board design, I want to answer your original question, for anyone else who might scan this post.

For the LP38513-ADJ you would look for a heat sink for a T0-263 package or For a D2PAK. It will be surface mounted and fit over the top of the package. Several heat sink suppliers have a version of this and you can ask your local distributer what they carry.

It will look similar to the following sketch of AAvid Thermalloy part #

Regards,

Marc