Hello,

I'm experiencing a 15% to 25% of failures at startup (or shutdown) for LM22670-ADJ. After some minutes it starts to burn and if power is not removed it eventually melts.

Vin=25V, Vout=12V, power consumption is lower then 1,0 A.

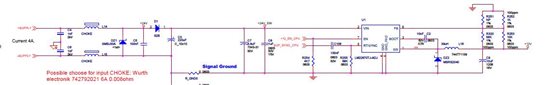

The schematic is the one below:

We did not experience this failure with the first small batch of production (30) but the failure came out at the second batch (>100).

The CPU is syncronizing the frequency at 500KHz and enables the device after about 10 seconds from power on (when CPU finishes other stuffs).

Any idea of what can be the problem?