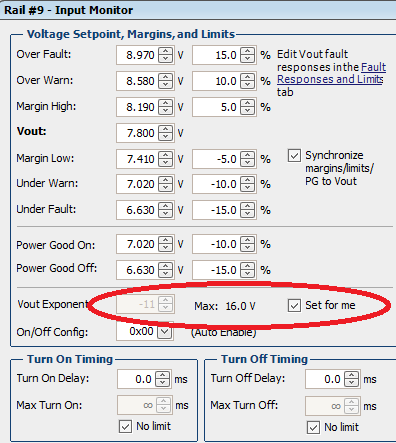

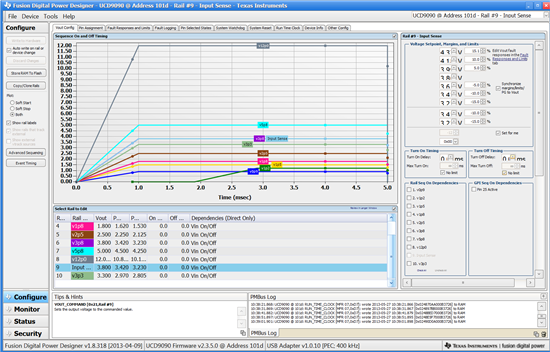

My customer has been battling my way through this UCD9090 part and it's GUI. they have come across a situation that I have so far not been able to resolve. They have assigned a 0.025 divider to MON11. When they enter the scale factor, or anything else lower than about 0.112, the reading just instantly drops to zero. Their MON8 connects to a divider for 12 V, uses 0.110 as a factor, and works perfectly.

They are using software version 1.8.318, dated April 9. Any ideas?