Hi,

TPS62360(YZH package)'s pad-to-pad distance is only 0.5mm, and it is impossible to route middle pads out without using via-in-pad technique.

We have also checked the EVM design, and it is very clear that EN and VSEL0 pins are routed out directly using via-on-pad.

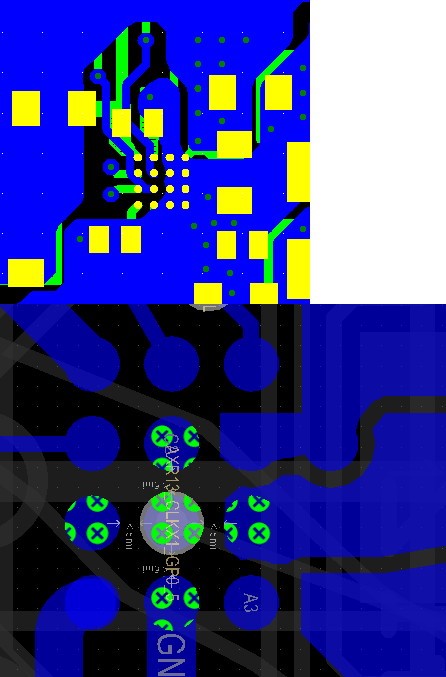

However, there are known drawbacks that solder will leak through the hole, usually causing loose/defective joints. Have the 62360 EVMs been tested for reliability? Is there any special technique used for enhancing the solder joints for via-in-pads? For example, is the EVM's via-in-pad filled with copper (left of image below, see article) or epoxy (right)?

In addition, using standard via size (hole 8mil, diameter 16mil), our EDA software reports that the distance between the edge of the via and other pads are too close. Is there any recommended via-in-pad dimension in terms of hole and pad diamsters for TPS62360?

Matt