HI,

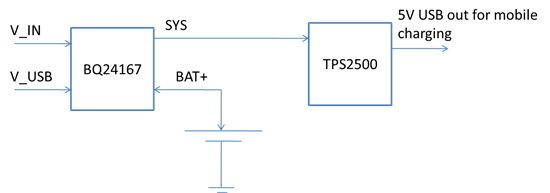

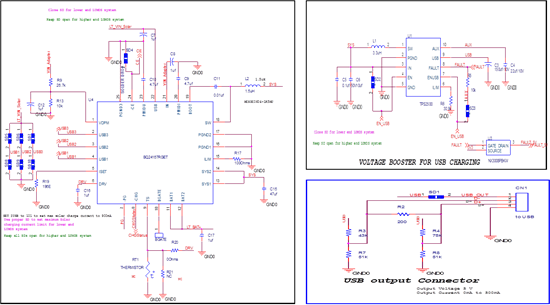

I am using BQ24167RGET dual input charge in my design.

In both charging & discharging phase i am hearing hum sound.

I am suspecting the noise is generated by the inductor.

As per reference design i am using "SPM4012T-1R5M" inductor.

Inductor :- http://www.digikey.com/product-detail/en/SPM4012T-1R5M/445-15778-1-ND/4328074

Current limit setup:-

Maximum AC charge current limit is 1.5A.

Maximum USB charge current limit is 900mA.

Even for some lower current i am hearing hum sound.