Hi TI Team and Forum

I have some questions and issues to treat. I will be very pleased if you Mastermind/Geniuses help me solve this specific questions

I have been playing with the BQ24650 circuit and made my own PCB and for truly understand the functionality I have came up with this questions.

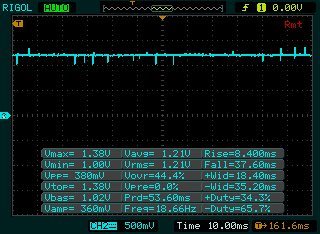

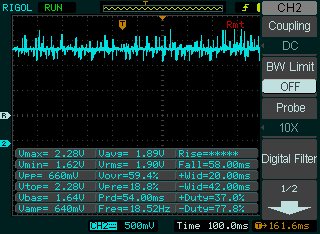

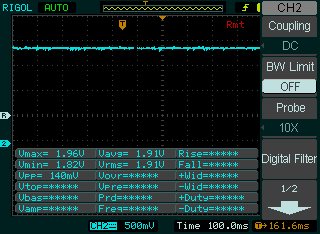

For reference, I'm using a 12 Volt Lead Acid Battery with a charging current maximum of 1 A. I have used the application report for making the modification with another transistor and resistors for pulse charging

1. In the application circuit of the eval board , D2 and R5 in junction with C6 creates a Boostrap circuit. Please clarify if correct and its properties

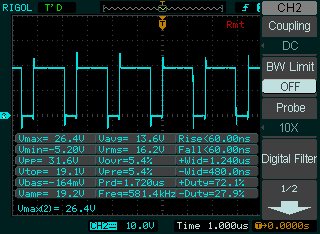

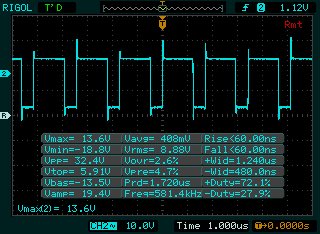

1.1. How could I know ( by measuring) if the boostrap capacitor is being properly charge and discharged?

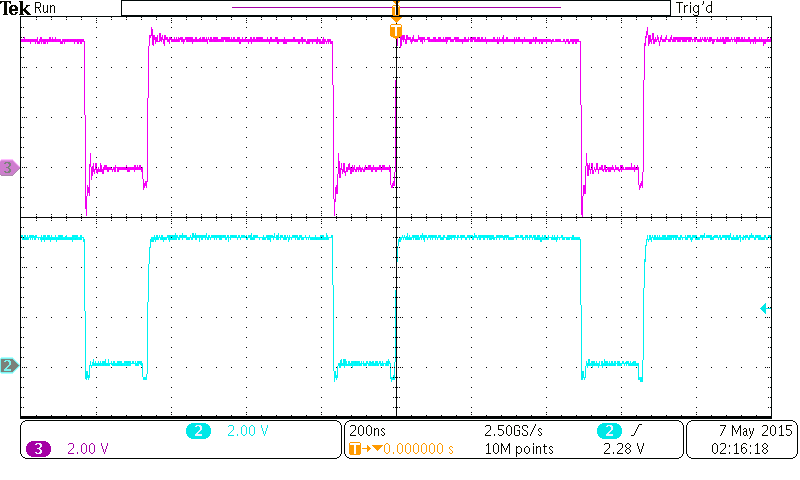

2. In the Eval board, C9 and R8 are designated for a snubber circuit, please clarify if correct. If its intended for a snubber can you recommend the values of the components, thanks.

3. In the Eval board circuit, what is the purpose of C2 C3 and C1 ? How can I use them to improve a functionality of my circuit? Are the values from the eval board a good reference value or can they be improved?

4. For the output capacitor's labeled as C7 and C8, should we considered the DC bias characteristic of the capacitor to calculate the effective capacitance? Will this corrected value improve my efficiency?

5. I think is already solved but can you please re affirm if I can remove the input diode D1 knowing the risk of reverse polarity ? Or does it takes part of the input filter?

6. Im not using the Vsys Diode (D3) so I removed it. Was this a good practice or should I leave it ?

Thanks for your help Geniuses !