Hello Sir,

I am planning to use 7nos of (1Watt, 3.3V, 350mA, LEDs ) for making 7 Watt AC LED bulb using LM3444 (non isolated, buck mode), I have gone through the datasheet and I hope it is possible. My question is : Is there any changes or modification required for making the best use of LM3444? or The design I have considered is allright? Any tips from the experts.

Also, if successful, I am again considering for using 5 nos of (2Watt, 3.3V, 750mA, LEDs) for making 10 Watt AC LED Bulb using the same LM3444? I am starting from scrap, from Grass Root level, so any feedback or advice or suggestions will be much more helpful to me and highly appreciated.

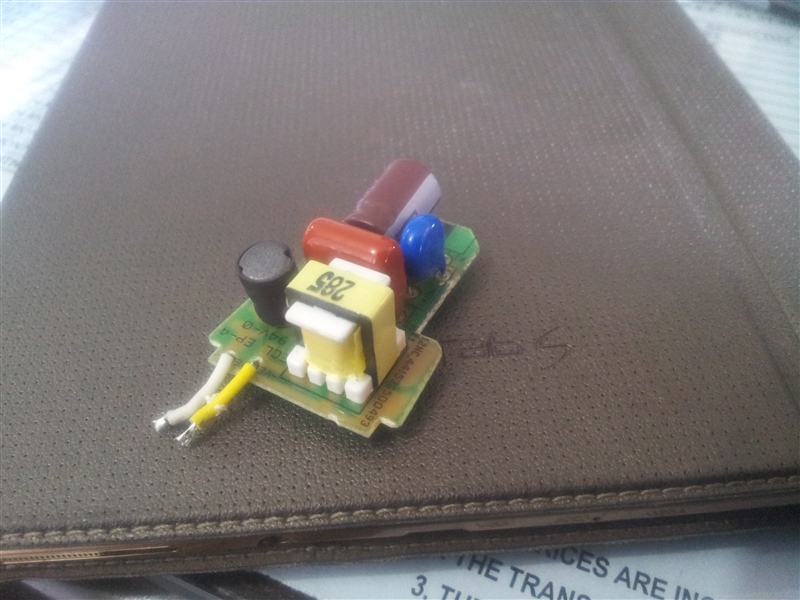

My main concern for using this LM3444 IC is to make the BOM footprint as small as possible to fit in the LED bulb casing.

Also there is one IC from BPS, IC no is BP2832A, which is also another option for me, and the component count is very low as compared to LM3444. So, am in Dilemma which IC to choose. Asking for sincere and honest advice from the experts. Thank you.