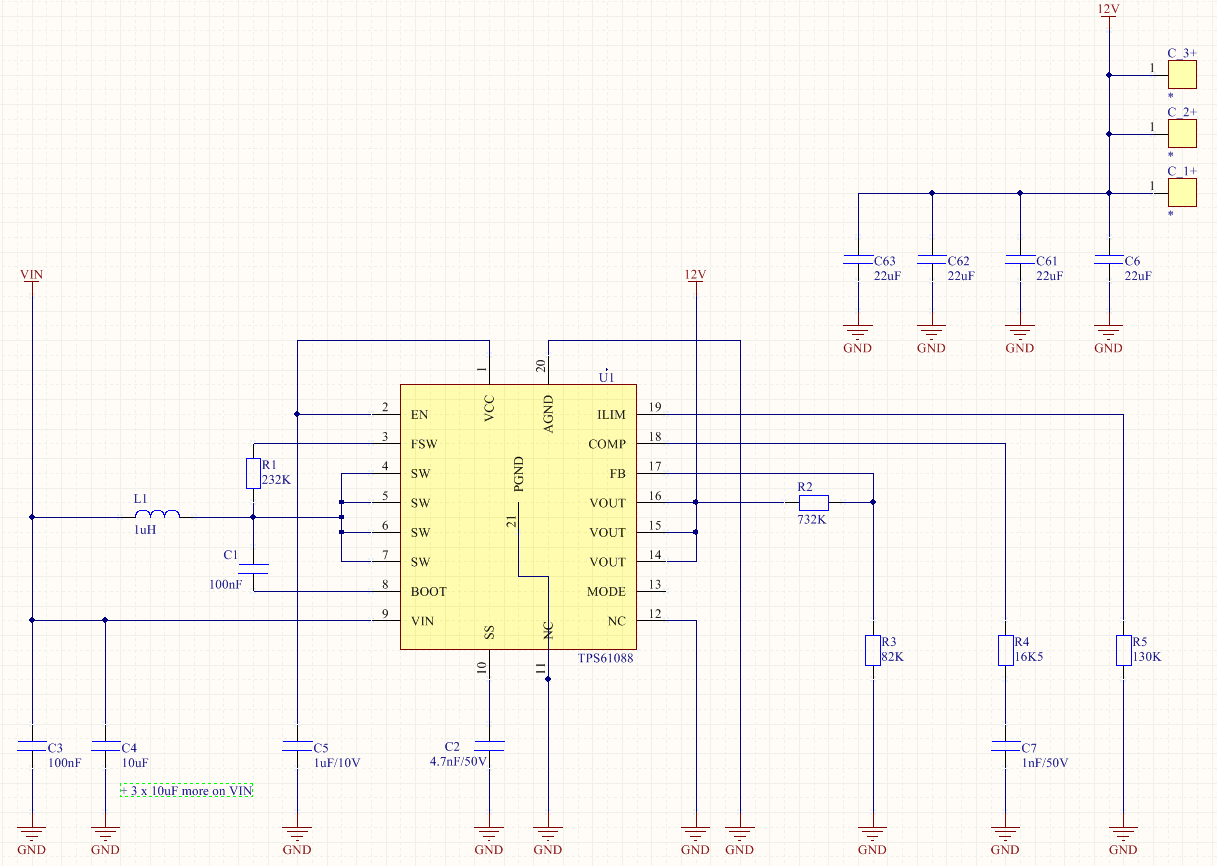

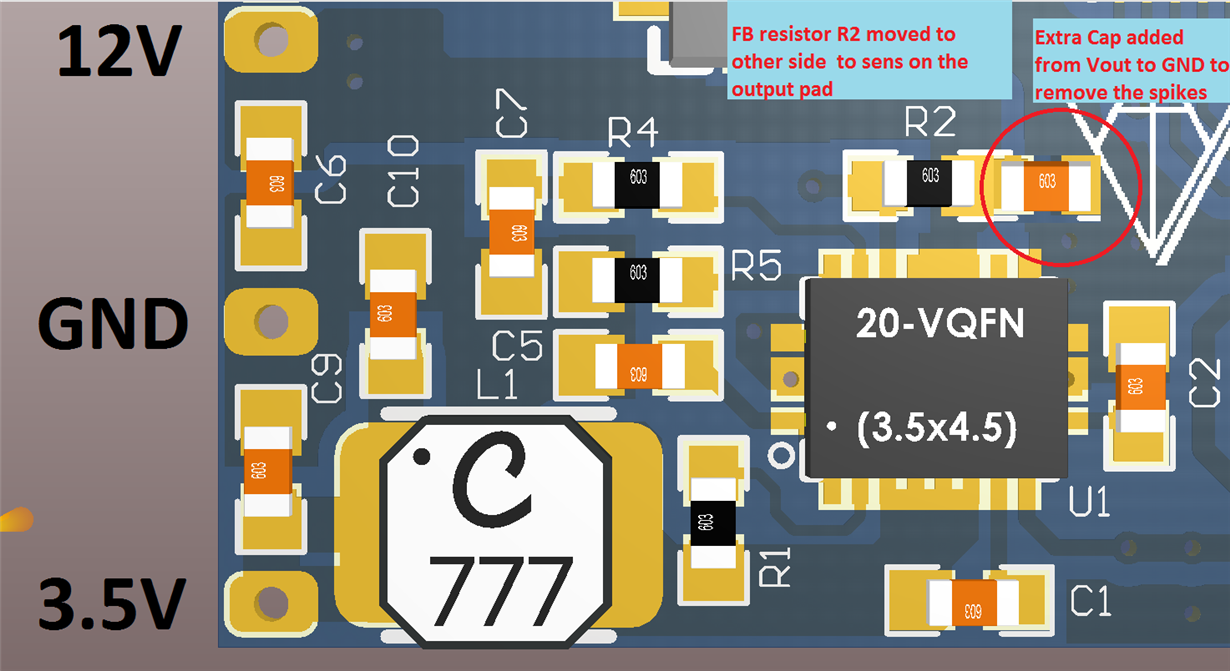

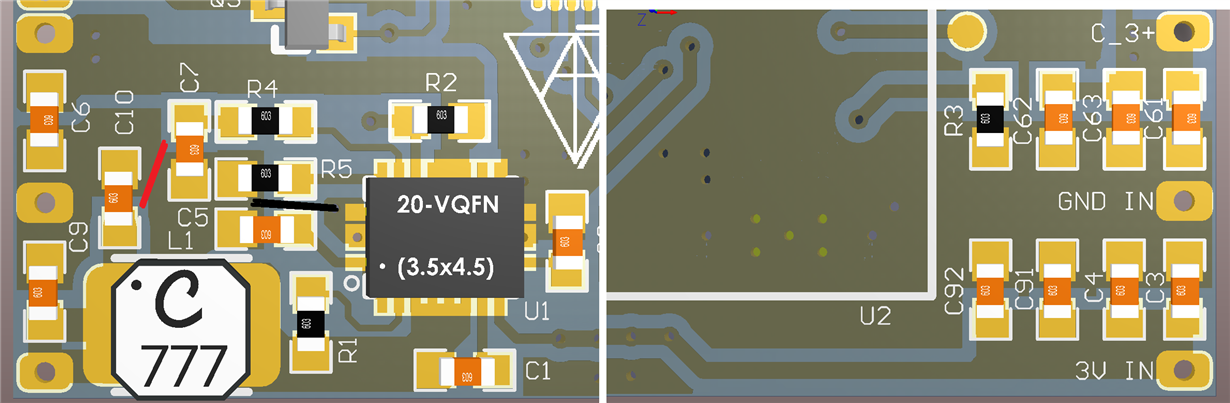

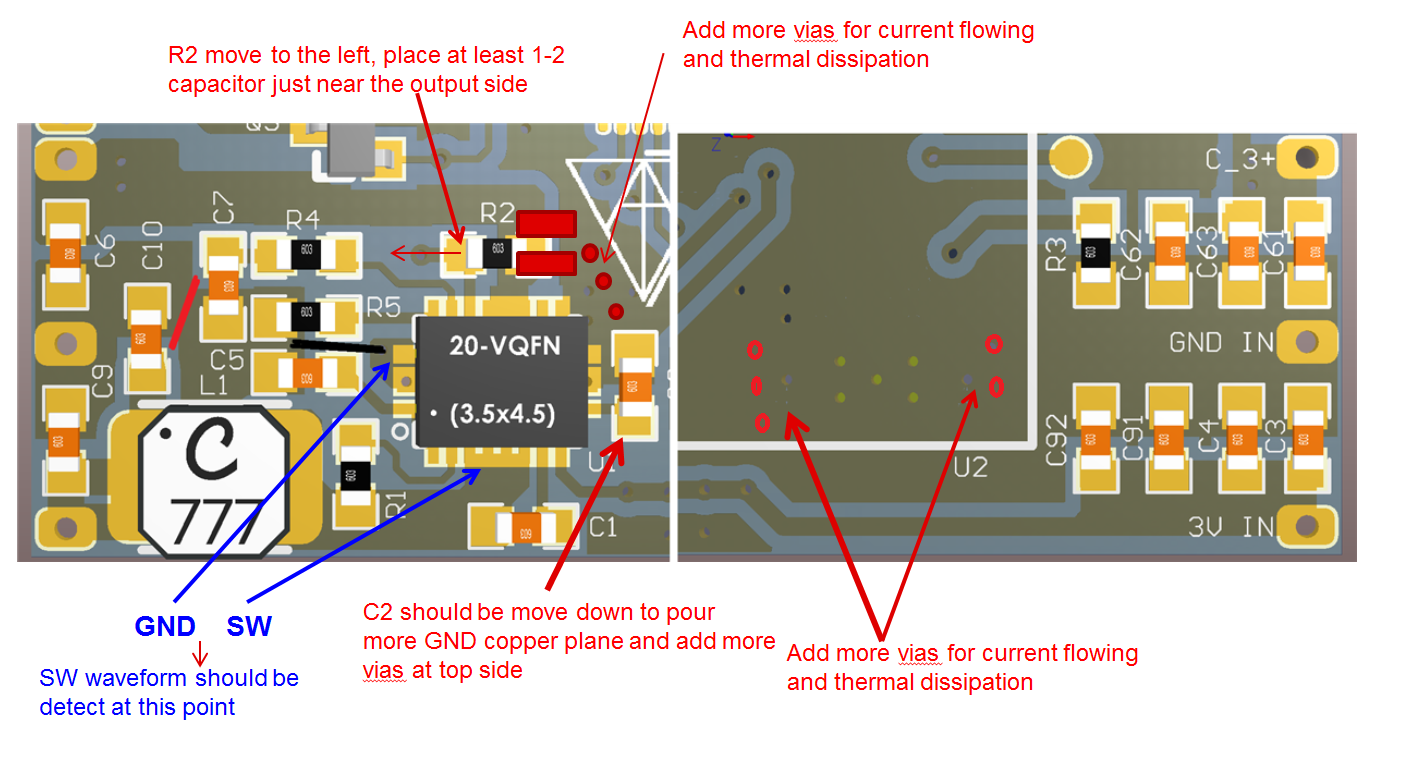

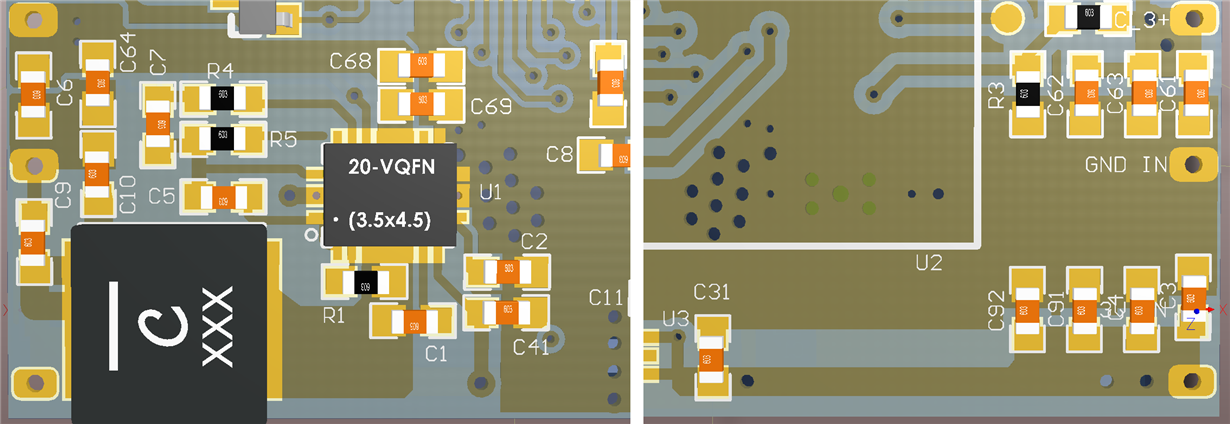

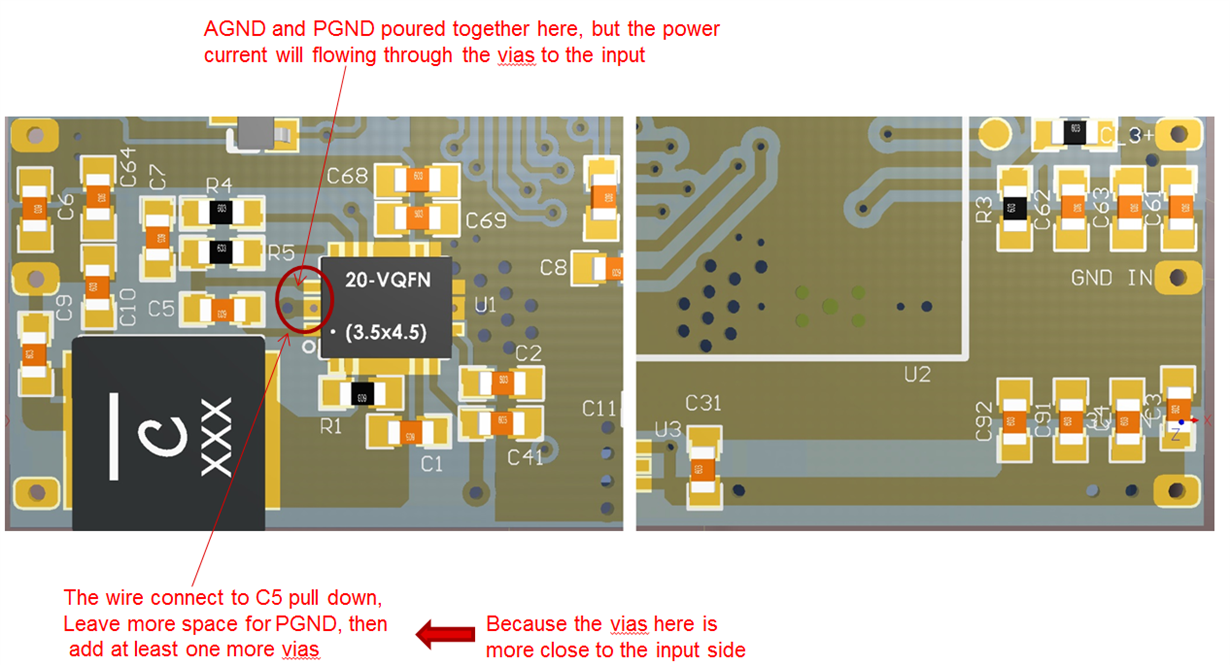

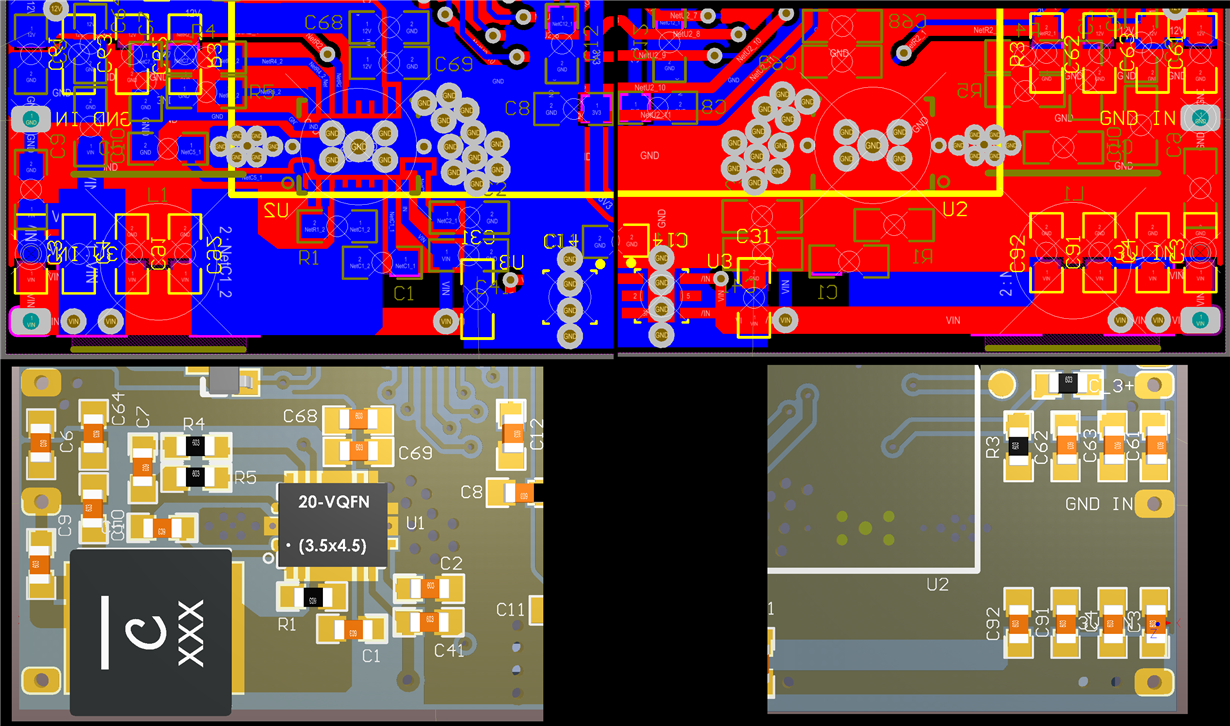

I have the below schematics. I need on output 12V 0.6A, but let say 1A to be on safe. I built it and first tried with XAL4020 1uH. It has the 12V on output, but once increase load it drops, and IC burns. I have bought the developer board and that works fine. Changed the inductor to XAL6030, it increased the loadable current, but still burns some ICs. Changed the inductor with that one from dev. board, seams to be better but still kills the IC at higher loads. Once the IC is damaged than the IC and inductor get hot, and load high current from source, but still try to work.

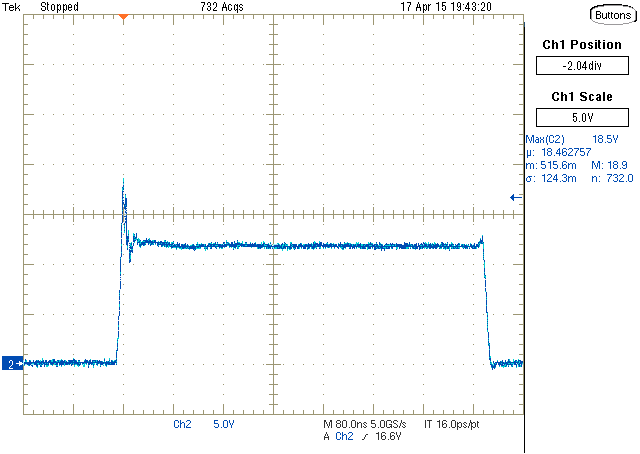

Looked at SW pin and it looks that my electronics has higher spikes than the developer board, that may kill the IC ?

Has anyone idea what Im doing wrong ? I burned already over 10 ICs, during trials.

Thank You so much !