Other Parts Discussed in Thread: LM3414

Hi teams

Background: My customer using 2 pics LM3409 on one board to drive two different colors LED, the LED number in series is not the same.

Setting: External FET parallel dimming, dimming frequency is 25Khz

Vin1=38V Vout1=22V Vin2=48V Vout2=27V two LED circuit using the same inductance value. No output cap

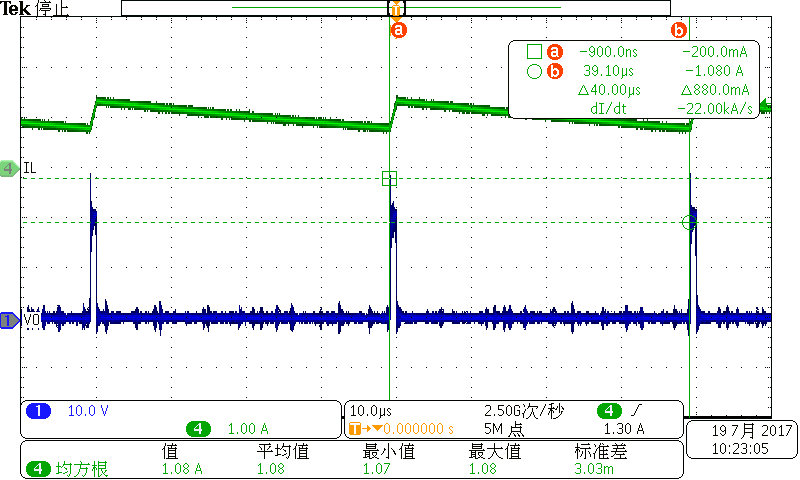

Issue: In low brightness dimming( dimming PWM duty cycle is very low) the LED current ramp up start point is different.

This issue won't happen when the duty cycle is higher.

Low duty cycle, the ramp up point is not the same

High duty cycle: The ramp up point is the same