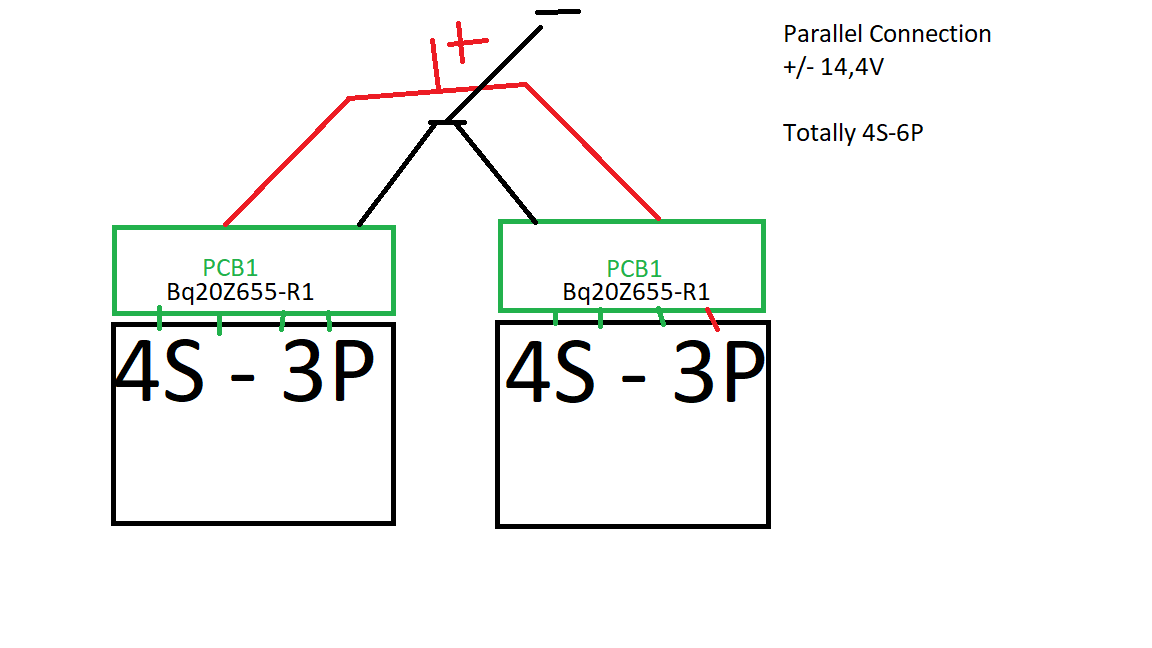

I am using BQ20Z655-R1 for a lithium ion battery which is in the 4Serial-3Parallel cell configuration. In addition, I don't use LED or LCD in this lithium-ion battery. My cells have 3500mAh capacity.

I am planning to increase the number of parallel cells but I am not sure about maximum number of parallel cells(for example 4Serial - 8 Parallel Configuration).

Especially, my concern is about cell balancing. Becasue internal balancing current is 5mA. What are your recommendations?

Note: I have to use this ready-made design

What are your recommendations? Can I use this PCB/circuit for 4serial-8parallel configuration?