I have a TPS61093EVM evaluation board from TI, as well as a custom made PCB featuring this part in an embedded application. Both the EVM as well as the custom PCB are suffering from fairly extreme excursions in the transient response and I cannot figure out what is happening. The fact this occurs on both the EVM and the custom PCB suggests this is not a layout issue on the custom PCB.

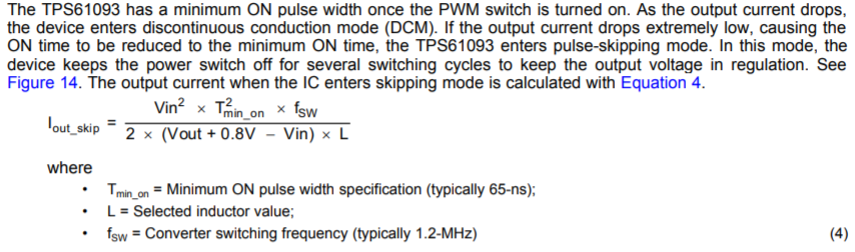

First, the evaluation board TPS61093EVM. Input voltage is 2.2V. Output voltage is set for 6.5V ( R1 = 121k, R2 = 10.2k ) by unsoldering/soldering appropriate value R's. Load is pulsed between 0mA and 70mA, 250Hz, 50% duty cycle. The load is an electronic load, verified through thorough testing to be accurately loading this output at 70mA. Everything else on the TPS61093EVM is untouched and stock as in the datasheet & user guide. Here's the output waveform, measured using a low-inductance barrel ground lead, directly across the output capacitor, on a 1GHz Agilent scope:

As you can see, I'm seeing negative excursions of almost THREE VOLTS when the 70mA load is pulsed on, and then almost 600mV of overshoot and slow recovery when it is turned off. This looks almost nothing like the waveform in the TPS61093EVM datasheet.

Adding a Cff of 10nF seems to quell the problem somewhat, but WHY is such a large value for Cff required here?

Now, the TPS61093 on the custom PCB is laid out in more or less identical fashion as in the datasheet suggestion and the EVM. Component values are a bit different, however. In detail: Cin=4.7uF 0603. Cout=2.2uF 0603. Inductor is 4.7uH LQH2HPZ4R7MJRL with 1.2A Isat rating ( this is 2x the maximum L current in this design, btw. I think L saturation is not an issue here) SS pin is connected to 220k/220nF in parallel. Cp cap is 220nF. Vo cap is 220nF. The green waveform is the applied load current of 70mA. Yellow waveform is the Co output waveform, without using a Cff capacitor:

Now, adding Cff = 10nF to the custom PCB helps matters somewhat, but still seems out of spec with regards to the transient response:

In the yellow waveform above, it seems Vout doesn't even recover in time to reach the target voltage ... the long slow RC ramp of ~4ms seems quite out of spec, as well as all the other transient behavior of this design.

Can anyone at TI or external provide any insight to what is happening here?

Why the large excursions negative/positive on both the EVM and the custom PCB? Am I not allowed to pulse between zero load and nominal load with the TPS61093? For the record I have tried all sorts of inductor values, all sorts of output capacitor values, and a wide range of values for Cff; the values stated above in the custom PCB give the "best" response according to my empirical observations, but that is still very short of expected behavior.

Thank you for reading!