Other Parts Discussed in Thread: LM2841

Hello!

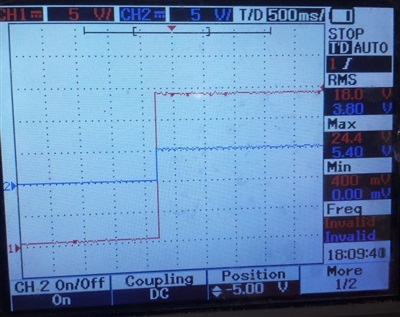

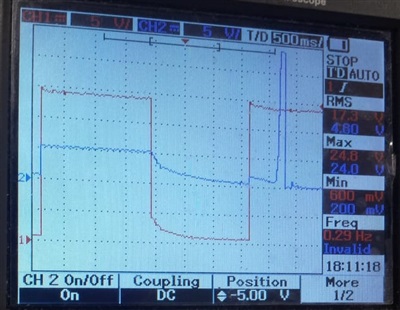

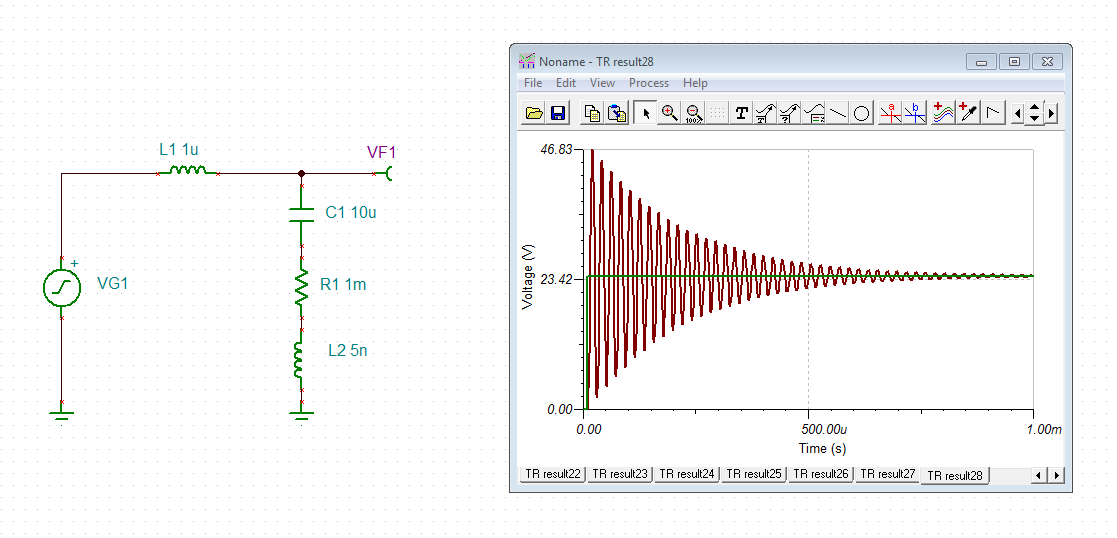

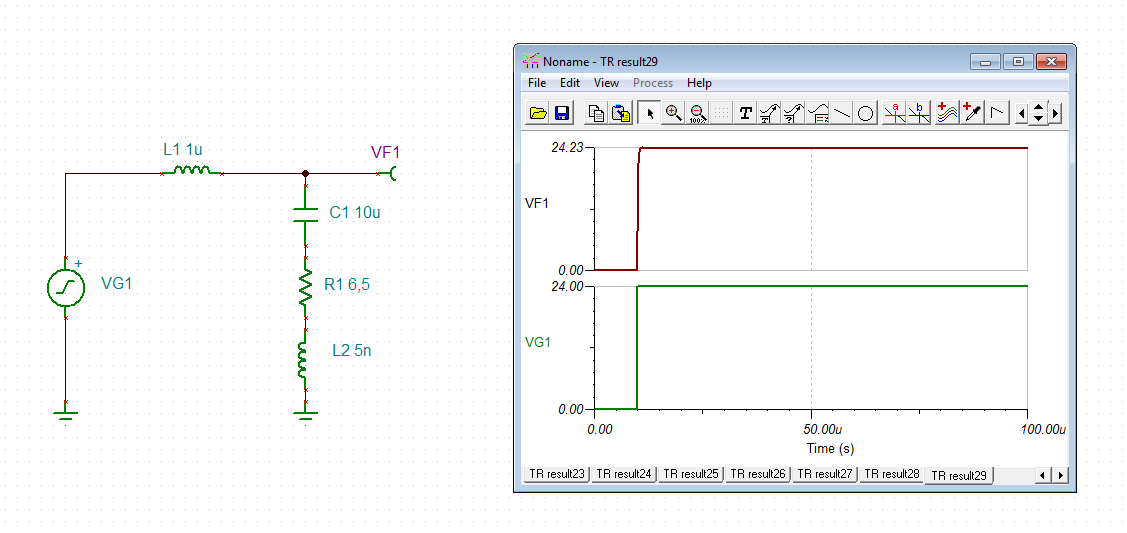

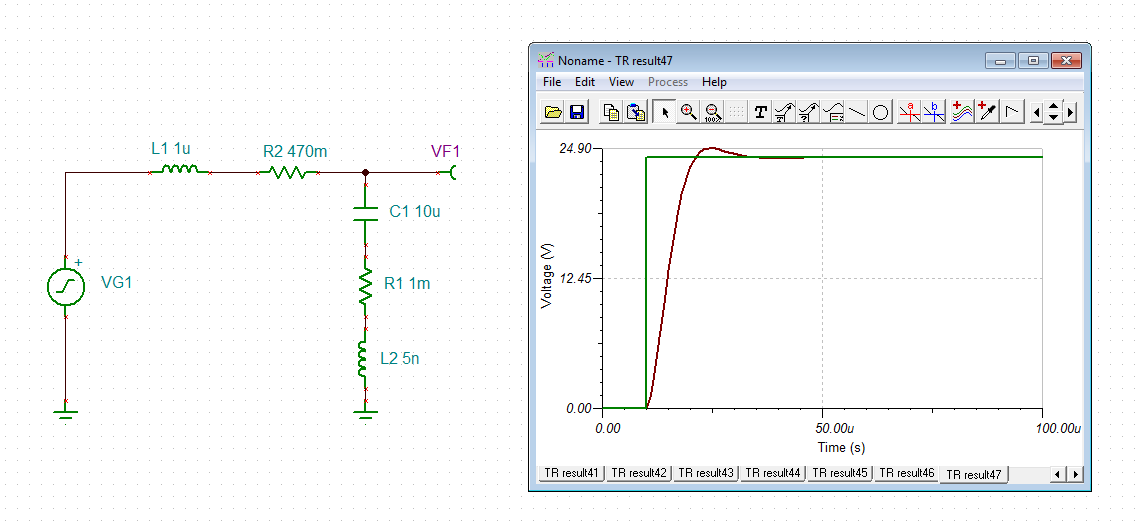

I designed a project that uses the LMR14203 converter. After mounting only the power supply components I noticed that, sometimes, after powering up the circuit, the output is short-circuited.

I noticed that the LMR14203 was the component that was short-circuited. After several testings, in some cases the LMR14203 stops working, aparently nothing happened, but in some cases, the LMR14203 burned (please see attached video).

I also attached the schematic e layout designs. After doing some tests, changing the input capacitor for a tantalum type (originally I was using a X5R dieletric ceramic capacitor as recommended in the datasheet), the problem didn't happen anymore. I was using a swithed power supply: 24V-5A. What could it be if I was using the components selected by the Webench tool?