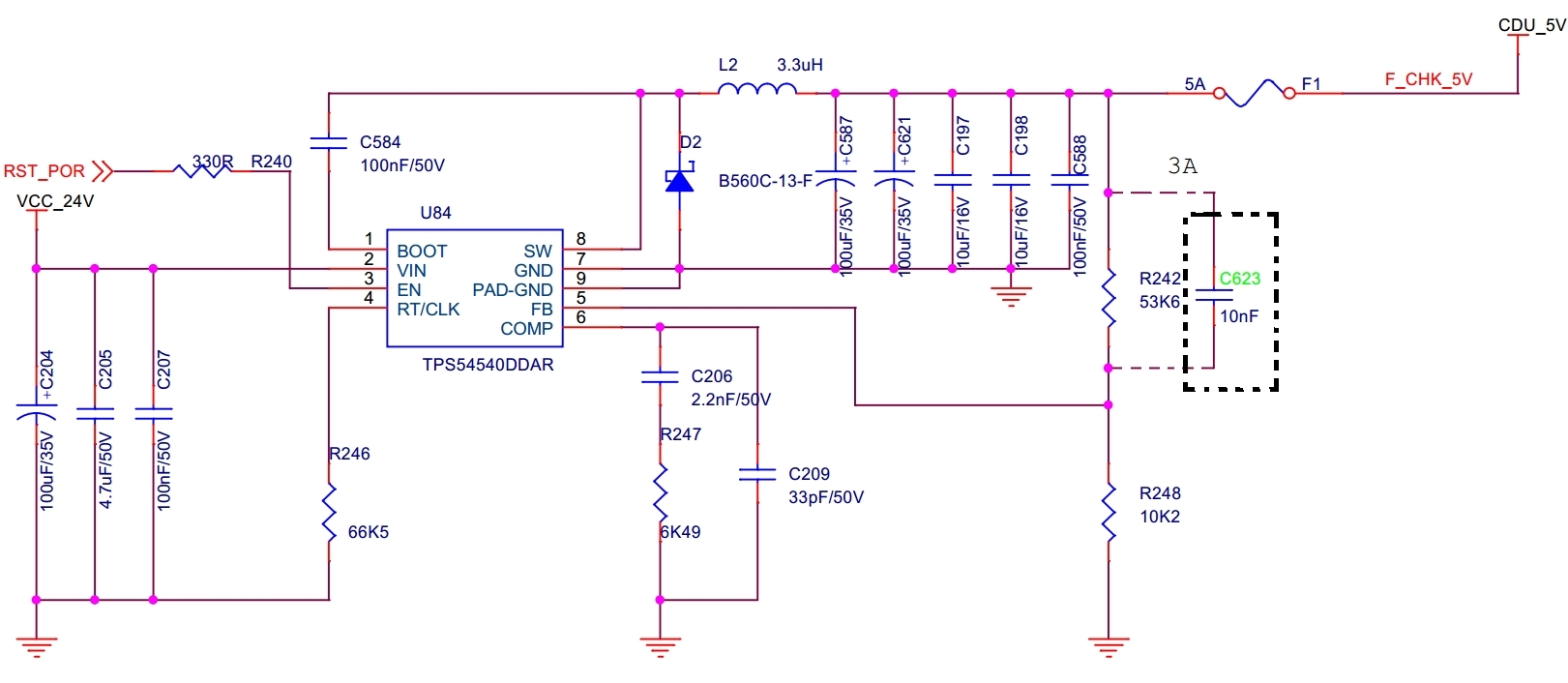

My customer is using TPS54540 to build 24V to 5V buck converter. The schematic is as below:

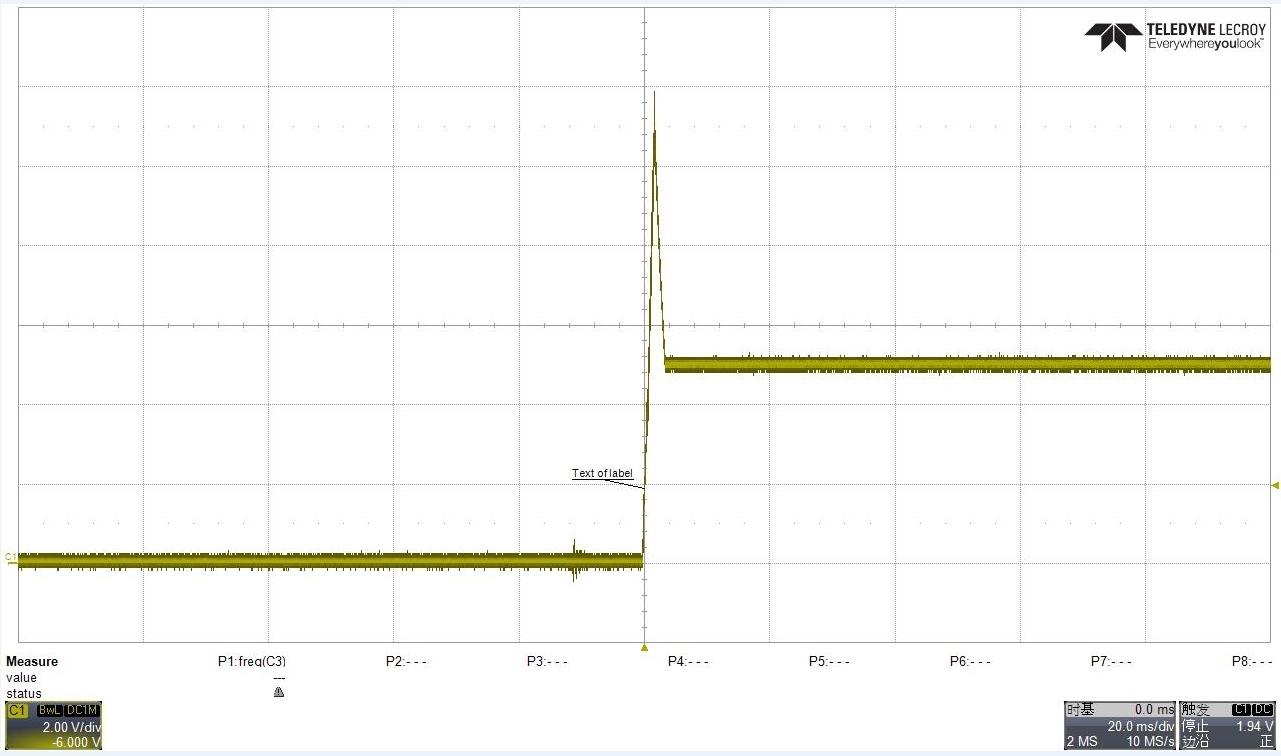

The output 5V has large overshoot at start up shown below:

The customer tried to add C623 in parallel with R242 and the overshoot could be reduced, but the output ripple will be bigger.

Could you please check if the schematic is appropriate and how to reduce overshoot without C623?