Team,

Customer found EMI issue when testing BQ24780S. It seems that it is caused by swtiching frequency 800kHz. EVM test result is better than customer system, but it still failed. Customer board PCH is 2 layers. Do you have any recommendation of how to improve this? I am assuming that EVM should be able to pass EMI test, right?

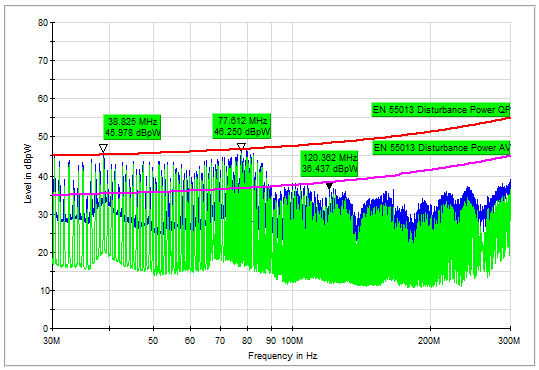

1. Customer system test result

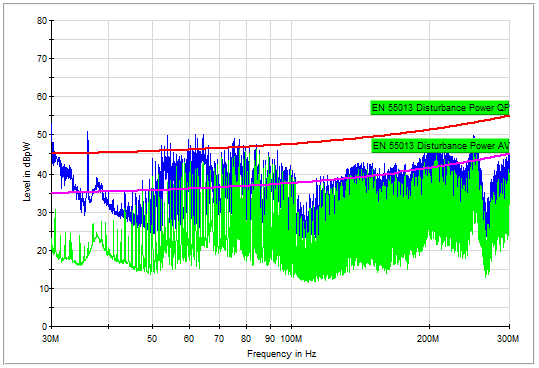

2. EVM test result