Hi TI team,

We're using LM431 in a Crowbar OVP circuit. We have been facing something strange in this use case of LM431; it is that initially the crowbar was triggering way above the designated threshold and consequently we made changes in the resistor divider circuit that defines the threshold for LM431, At this point of time the crowbar seems to be working fine but whenever we try to measure the reference voltage being received by LM431 using multimeter it triggers the crowbar, even though the supply is 5V.

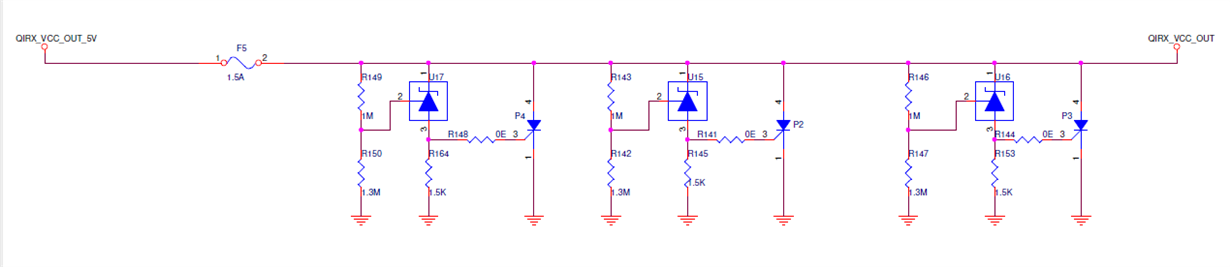

Below is the circuit: Version 1

Version 2: Modified resistor divider.