Other Parts Discussed in Thread: TPS62742

Hi sir,

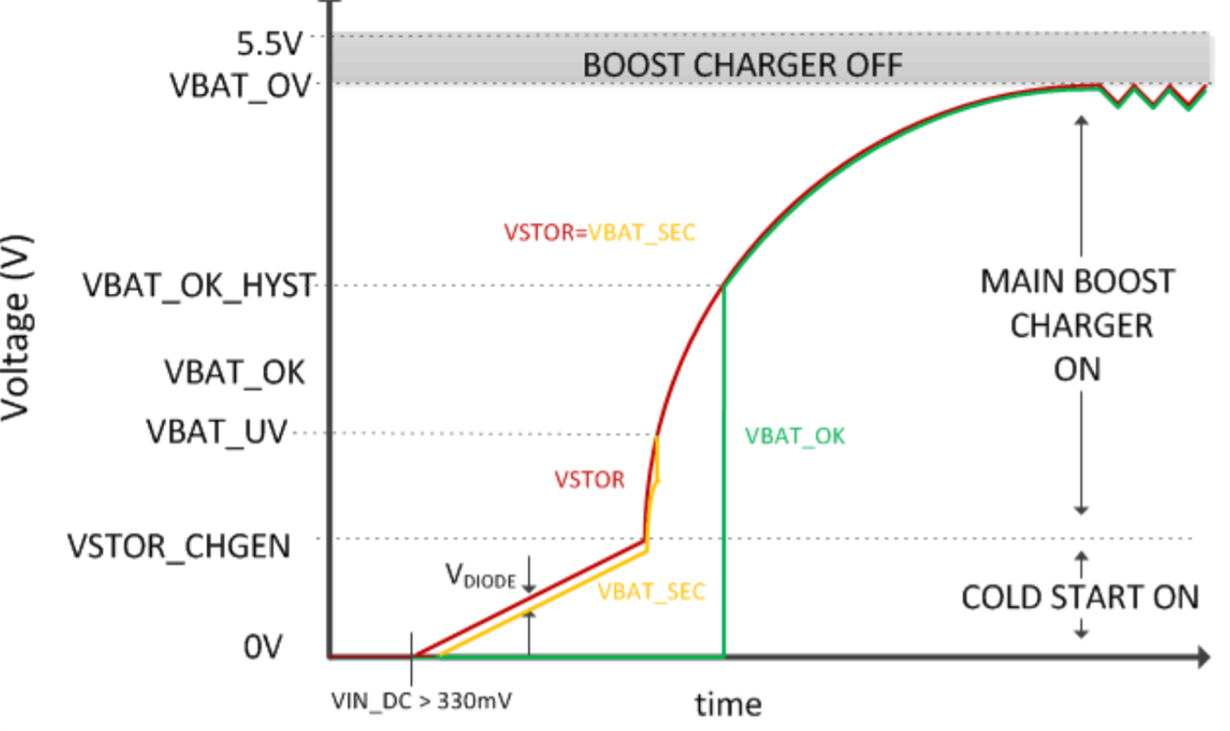

Follow the picture from datasheet which is shown as below,

When the VSTOR > VBAT_UV, internal PMOS will be opened that VSTOR will = VBAT. When VBAT arrive to VBAT_OK_HYST, IC will raise up VBAT_OK, Is it right?

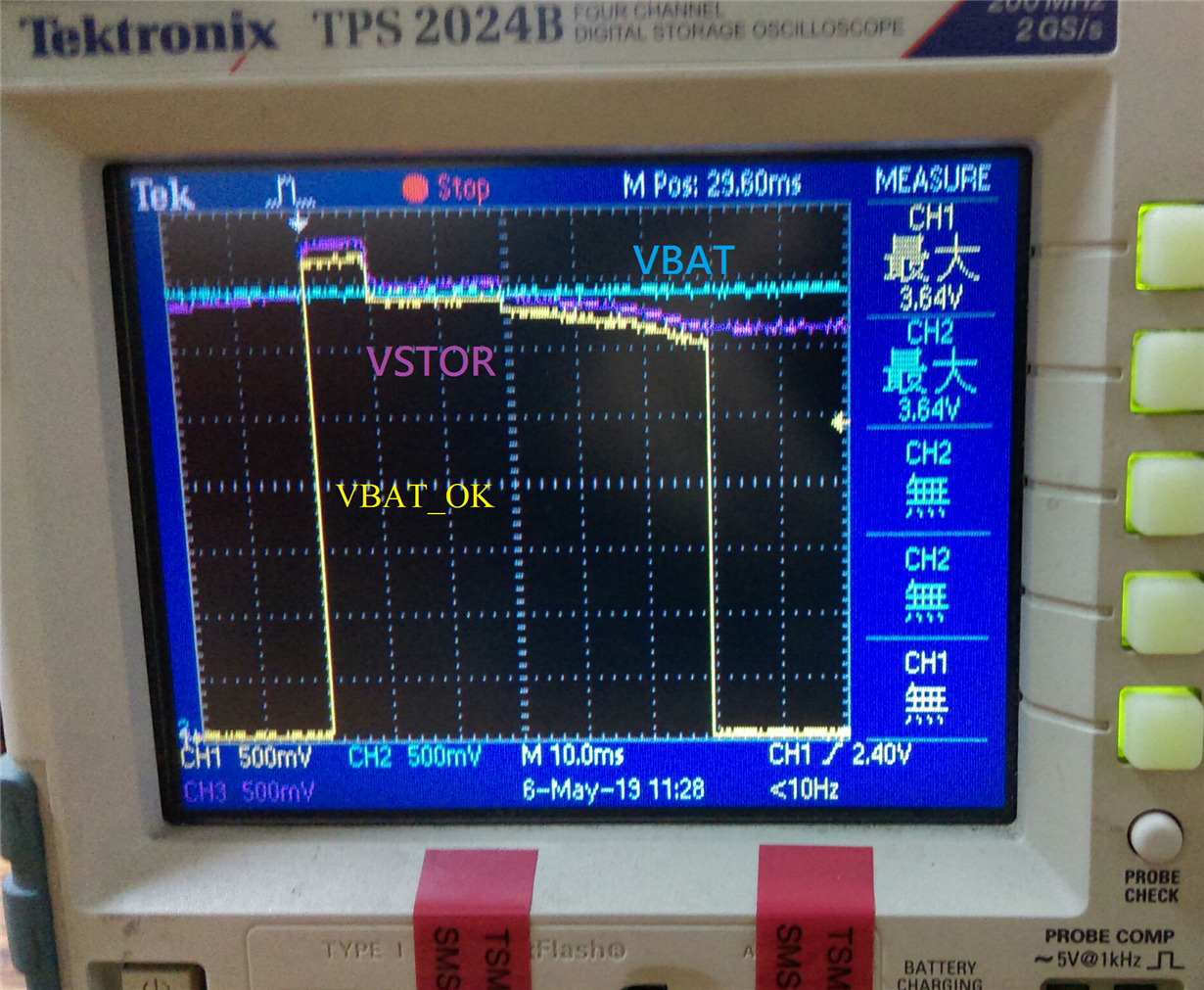

But we measure result from our board, we found the VSTOR arrived to VBAT_OK_HYST, IC raised up VBAT_OK .

Internal PMOS seems doesn't open, therefore the power can't keep the system work. System will shut down at VSTOR dropped.

How can we solve this?

Thanks.