Hi there:

I'd like to check a question for our customer about solder thickness for MPB package.

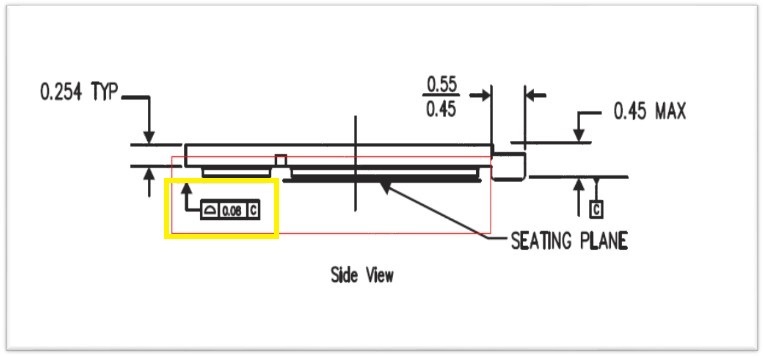

as we can find a specific 0.08 in data sheet.

but from slma007 this document, the figure 5, target solder thickness after refolw - Die = 50um (25/25um by dome print, On TAB =30um)

how could we understand those two part parameter?

Or 0.08mm is the max value for solder thickness requirement?