We have a design with the LM3401 with 3 LED's in series.

A 9V forward Voltage. 24V Input.

The first build of this was done in Feb 2017 in china.

The second build was done this year in the USA.

This is a MCPCB.

Both builds used the same GERBER's and BOM.

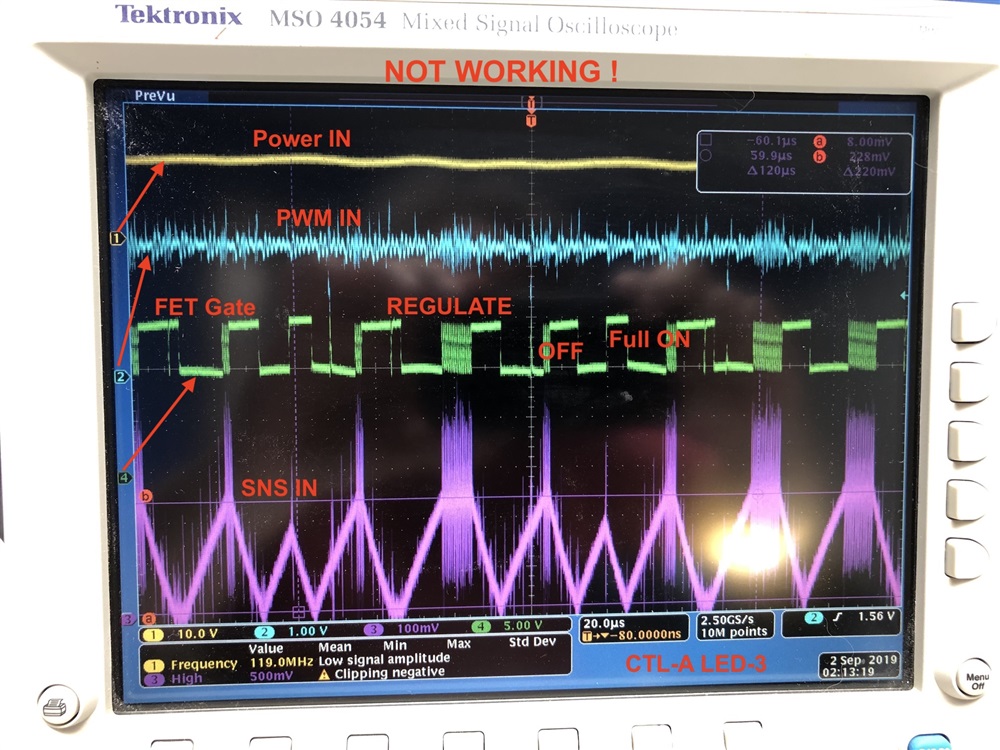

I see erratic behavior on the Gate drive that I do not know where it is coming from.

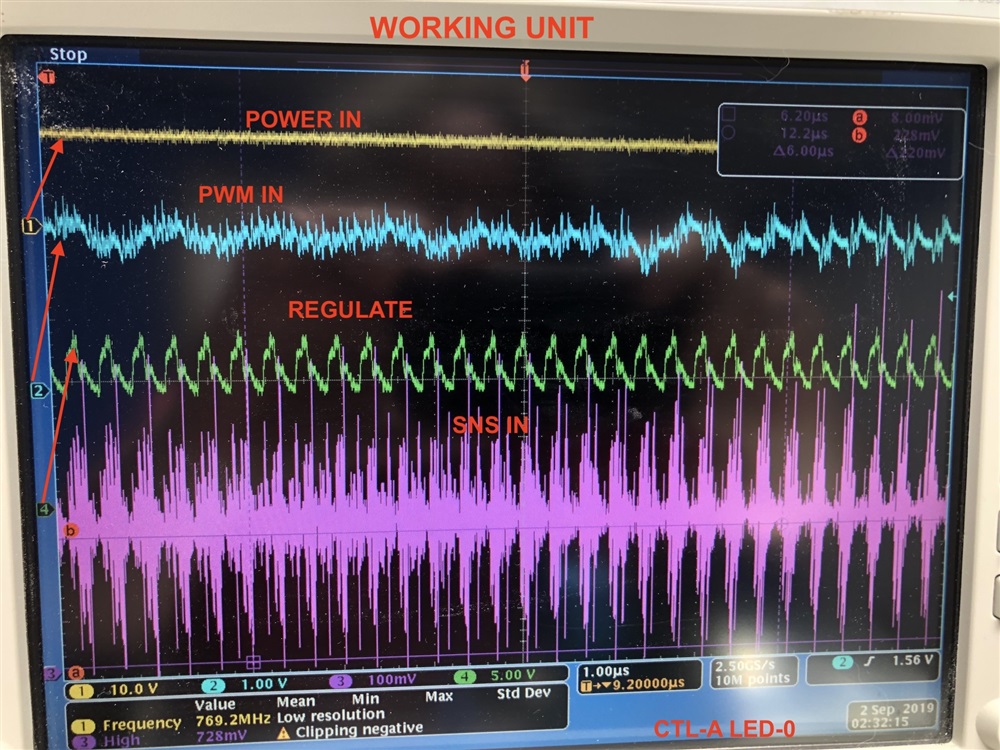

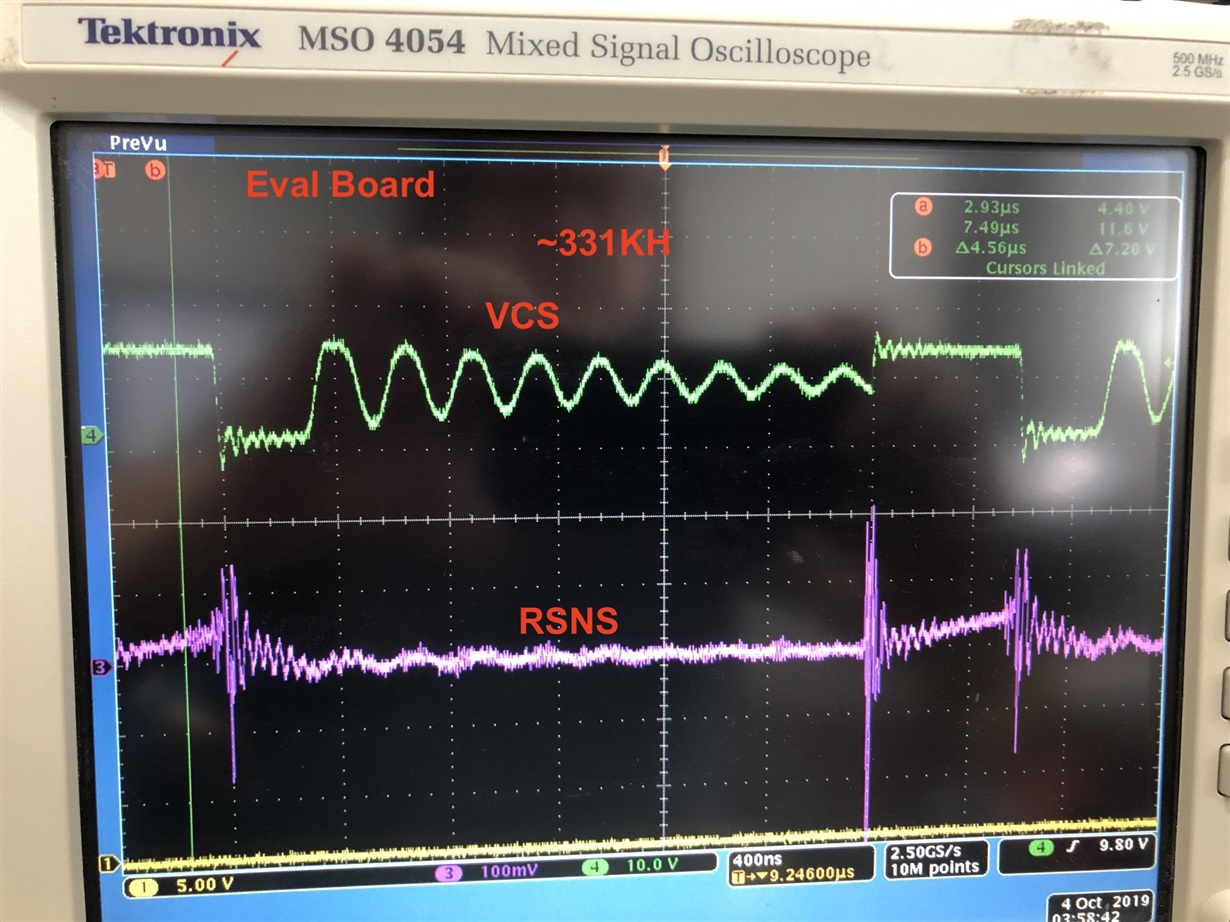

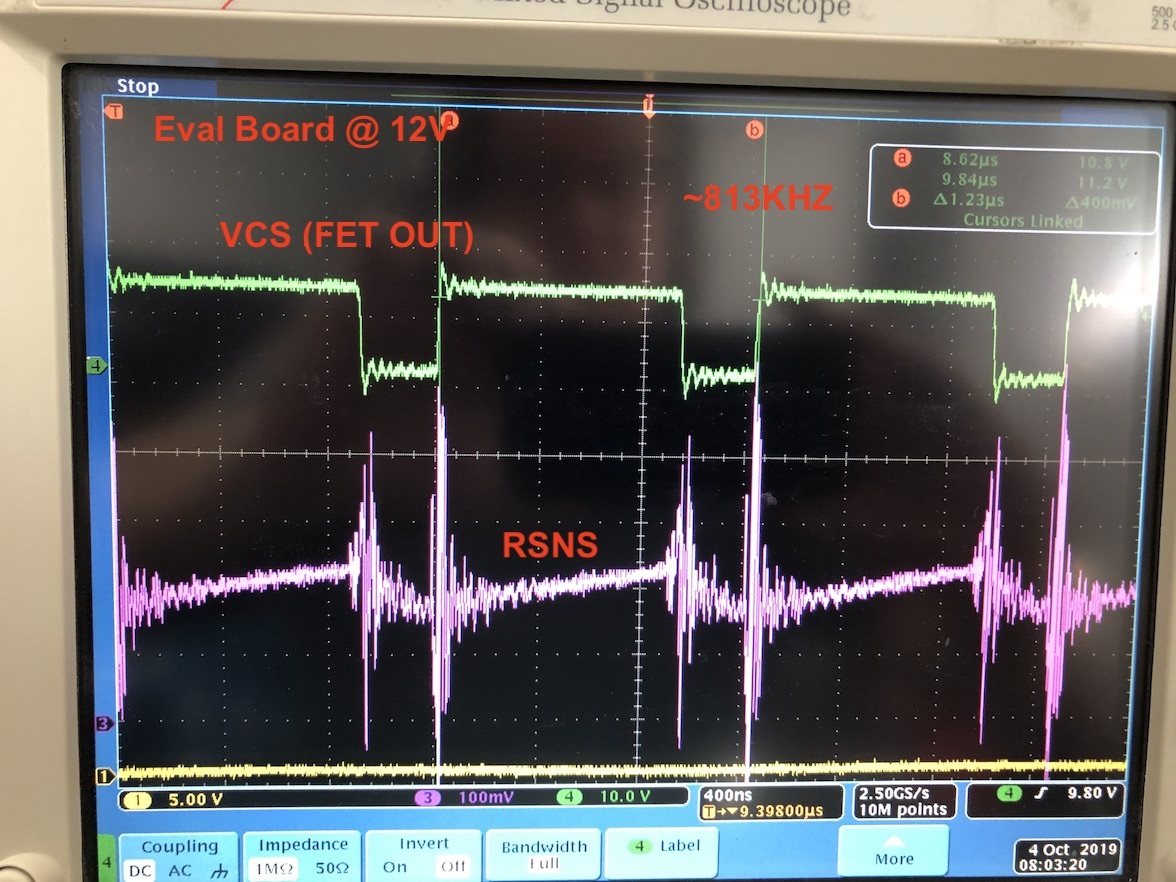

Working Unit:

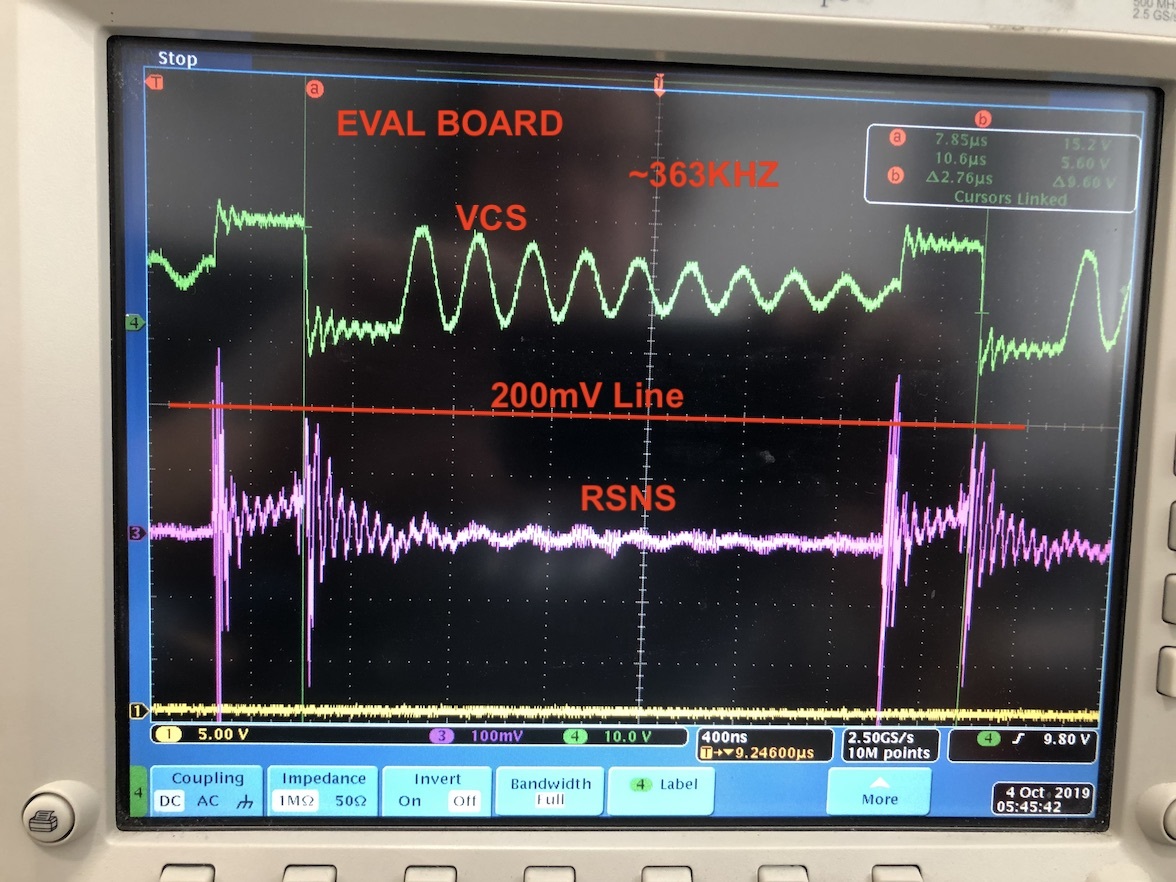

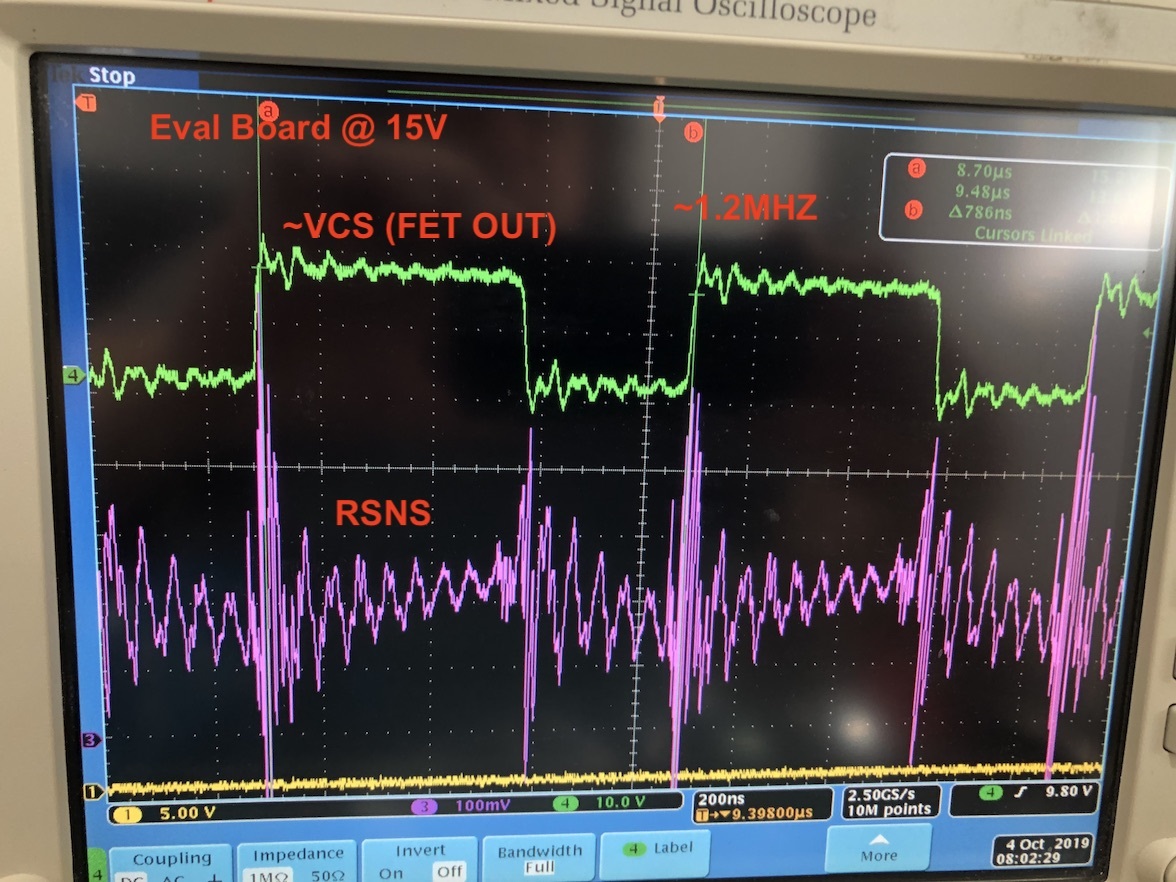

Not Working Unit: