Other Parts Discussed in Thread: LM5112

Hi,

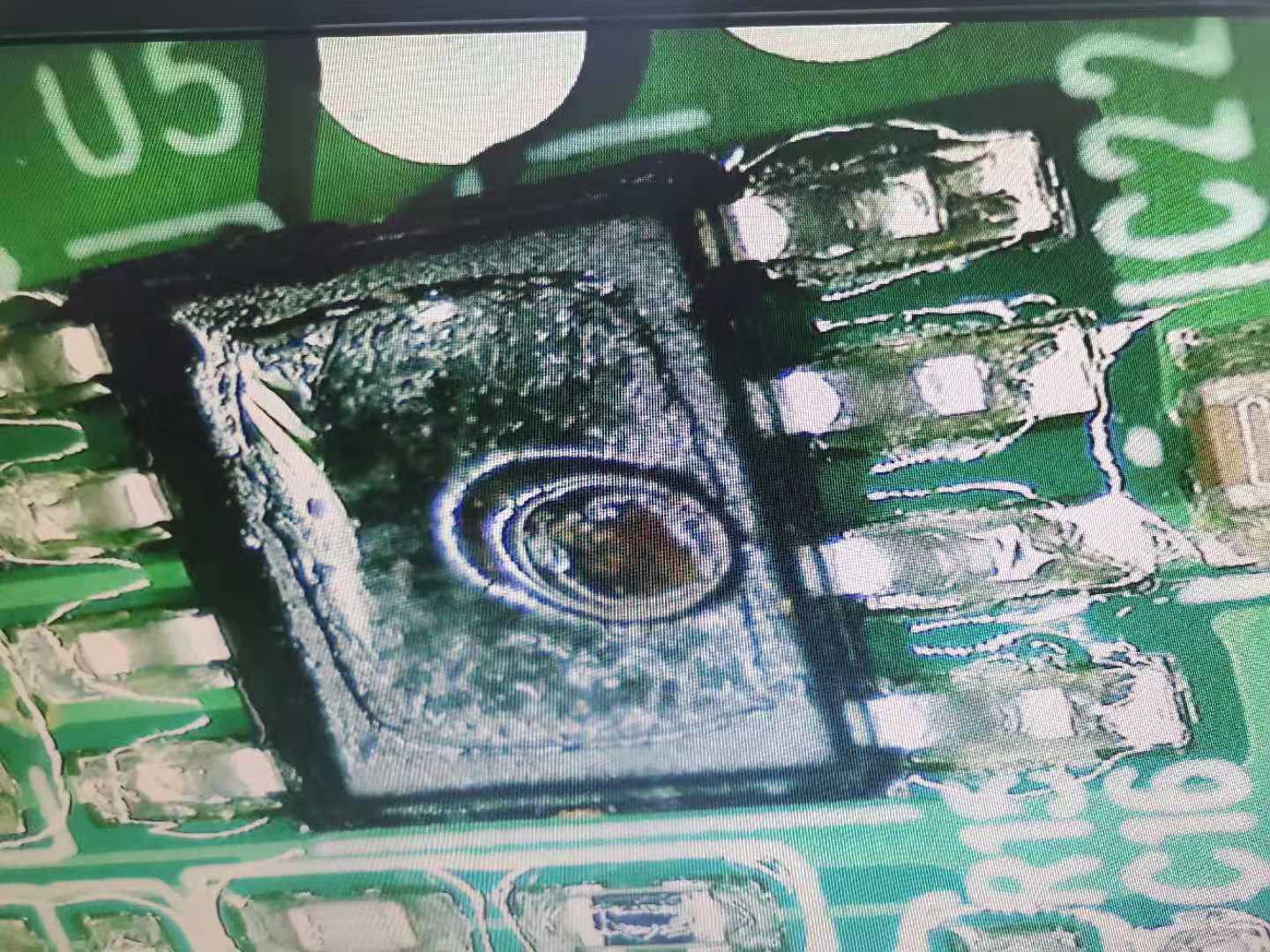

My customer use LM5111 as ultrasonic proble driver, but found several boards get fire and damaged as below first picture, do you have met similar cases before?

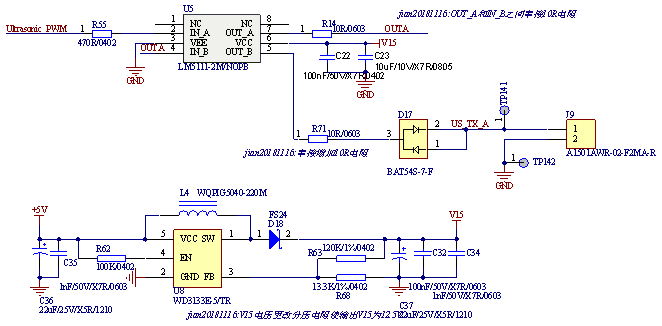

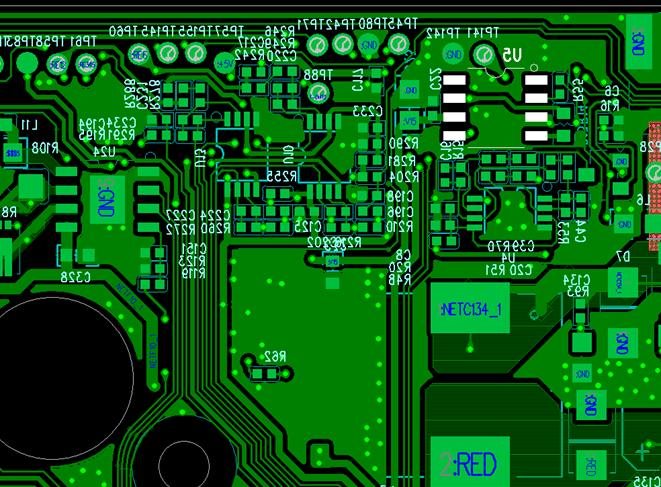

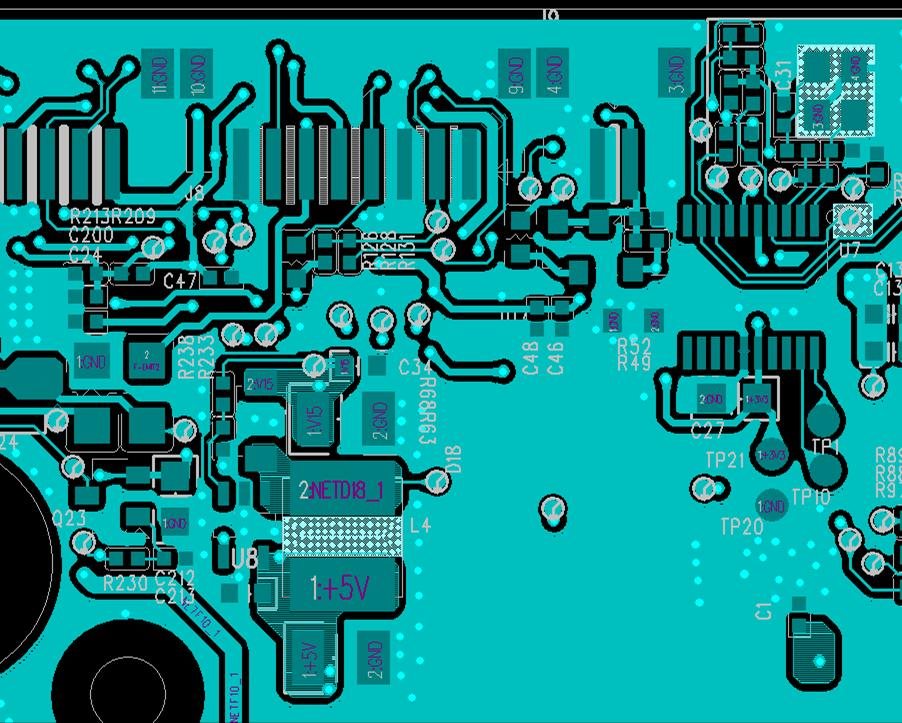

Schematic and PCB are attached as following, pls help give some suggestion, thank you.

Schematic:

PCB top layer:

PCB bottom layer: