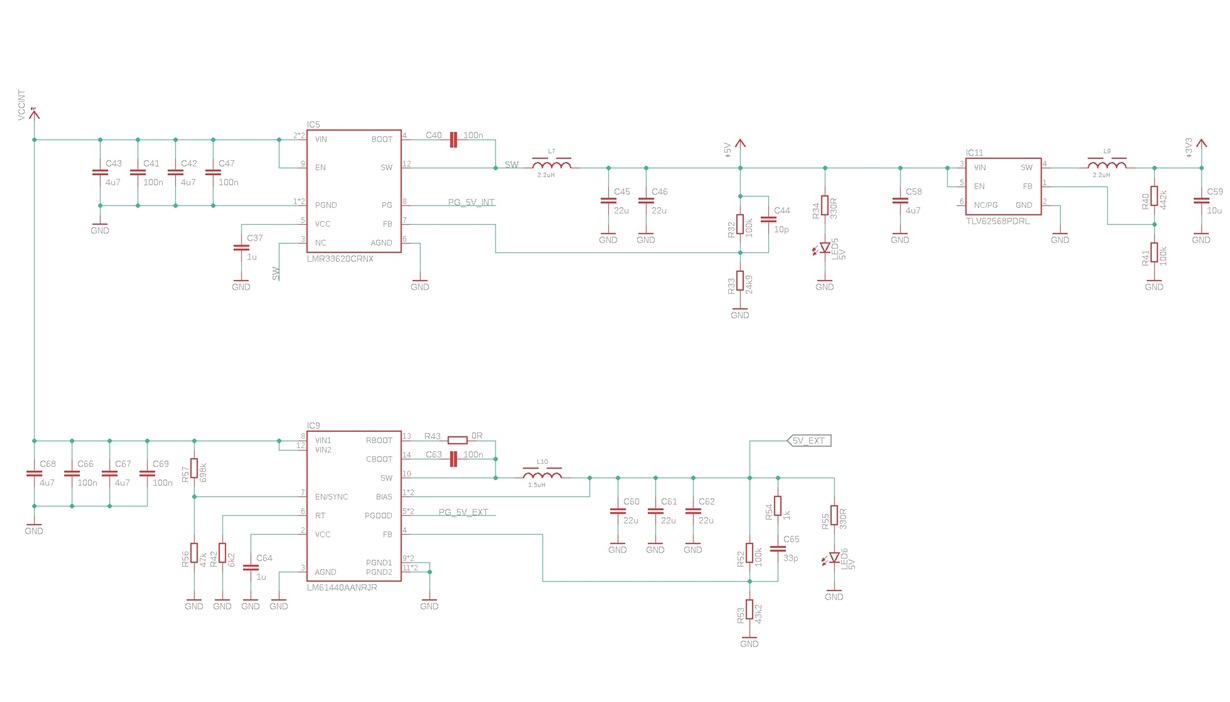

Other Parts Discussed in Thread: TLV62568, TPS22954, LM76005, LMR33620, TLV62568A, PMP15039, TPS22953, LM76003, LM61440

Hello TI team,

for an embedded project I am looking for a suitable concept for the power supply and a suitable switching regulator selection.

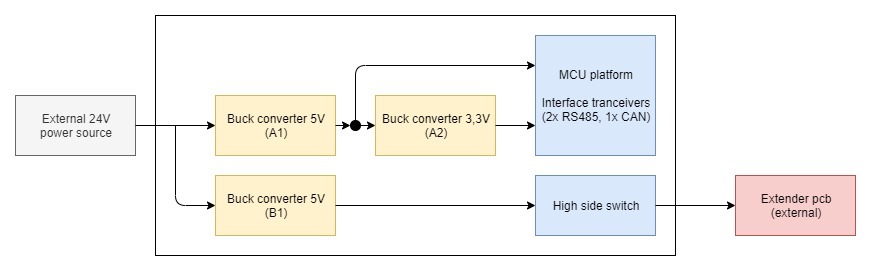

The system basically comprises a 32 bit microcontroller with external flash (QSPI), two RS485 interfaces and a CAN interface. Microcontroller, flash and the two RS485 drivers run on 3.3V. The currently planned CAN transceiver runs on 5V (VCC = 5V, VIO = 3.3V). The current consumption on the 3.3V is below 500mA (worst case scenario). At the 5V, only the CAN transceiver is supplied on board.

Our project also works with an extender board. The power supply for the extender board is provided by our board. The current consumption of the extender board is temporarily 5V / 3A - typical current consumption is around 5V / 1A. The power supply to the extender board should also be able to be switched off via the microcontroller.

The board is supplied with a voltage of 24V (nominal). My current concept of power supply is shown in the following diagram.

I currently selected the LMR23615 for the internal 24V to 5V power supply and for the conversion from 5V to 3.3V I focus on the TLV62568 (buck converter A1 and A2). For the power supply of the extender board I planned to use a seperate buck converter. The power supply must be implemented in a very space-saving manner (small common footprints and only ceramic capacitors).

My questions:

In general, is the design conception of the power supply reasonable and practical for this application?

Is the LMR23615 a good choice for this application?

Can the second buck converter be used behind the LMR23615 or would another buck converter be more suitable for this design? Would it be better to replace the buck converter A2 with an LDO?

Which switching regulator can you recommend for converter B1 for this application? Currently I have the LM76005 in the immediate selection. I researched the TPS22954 as a load switch. Would this be a sensible choice for the application to switch 5V / 3A permanently? What are the thermal requirements for the TPS22954?

Thank you for your help!