Other Parts Discussed in Thread: PMP20634

I am currently Working on a Flyback Converter Design based around the Ti UCC28730 IC.

My first Design is very similar to the Ti PMP20634 Reference Design, it is working how it should.

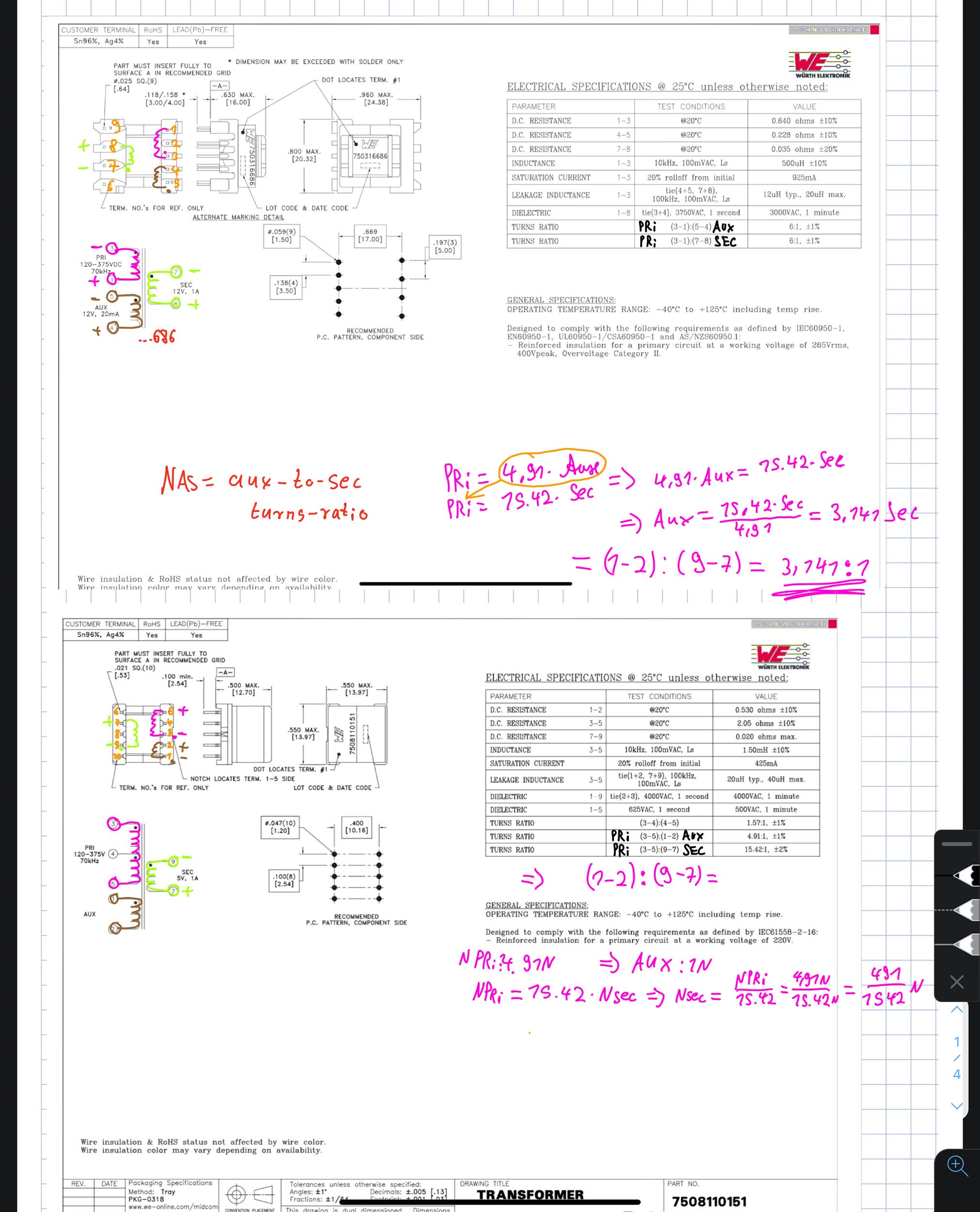

I want to use a smaller Transformer so I changed the WE750316686 to the WE 7508110151. I used the same exact PCB and also changed the MOSFET to a Infineon IPW65R037C6 on both designs, the first Design is still working with the new Mosfet so this should not be the problem.

My Output Voltage on my second design with the smaller Transformer is very unstable and I can only conduct around 3W before the Voltage on the Output drops to zero.

I recalculated all the smaller Resistors for both Transformers, this should also not be the problem?

The picture of the Scope shows the Source Ground Measurement of the circuit with the hot snubber.

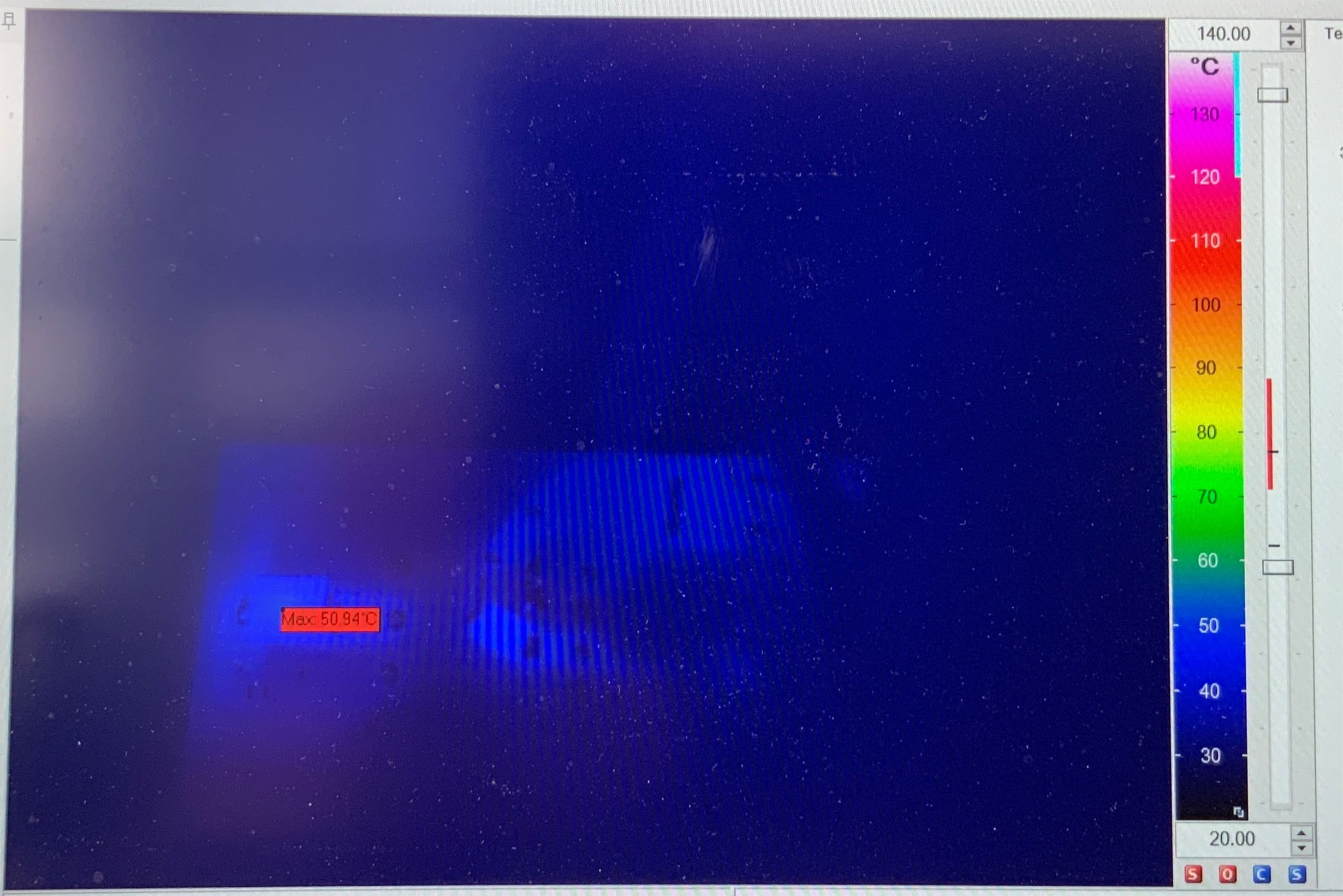

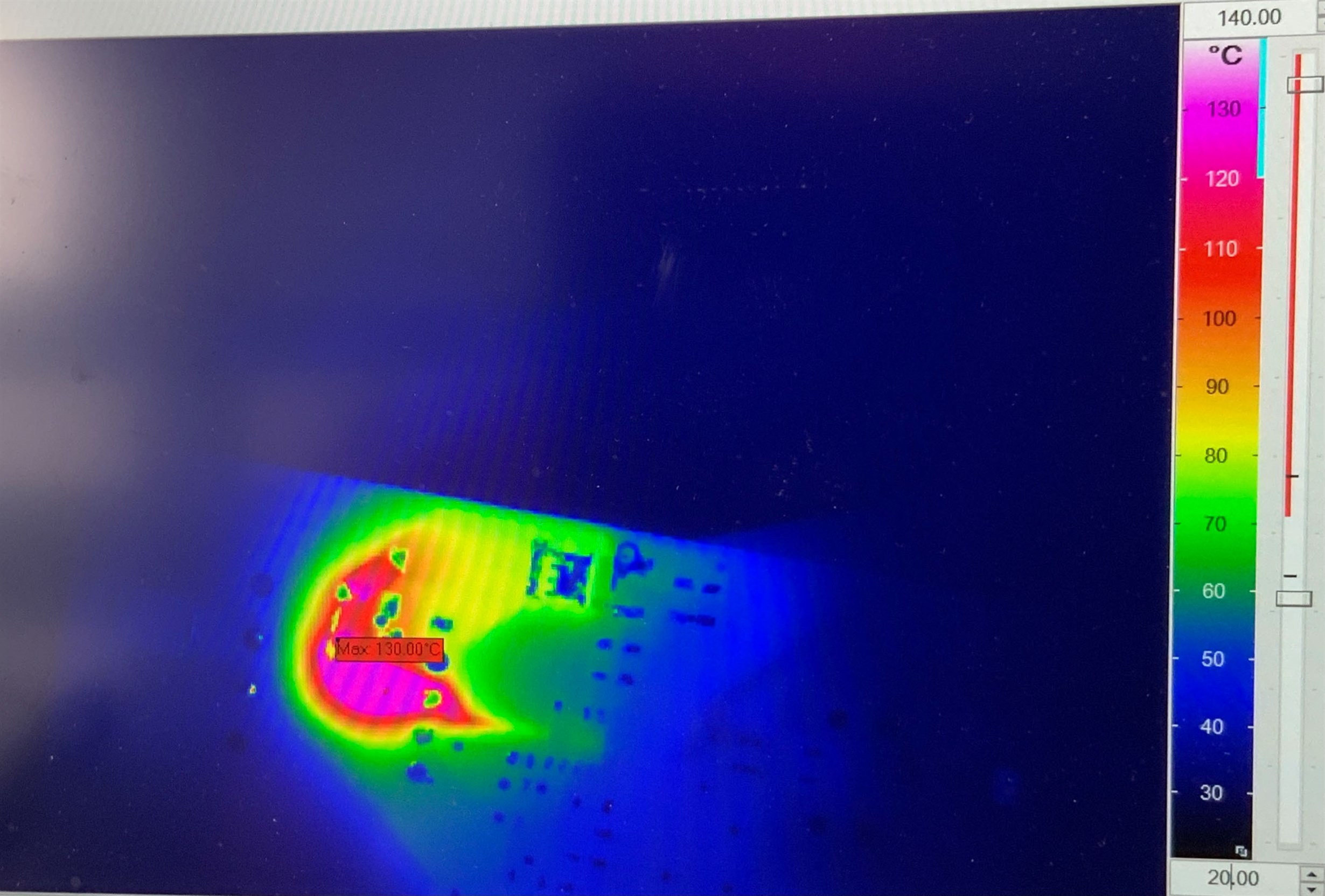

The Thermal Images of the two Boards (Diode D2) reveal that the Diode D2 on the Board with the smaller Transformer (7508110151) is getting very hot, so this should be the main problem.

I am pretty certain that I have to redesign my Diode Snubber, maybe a 200V Diode (currently 150V) would be the solution, is this correct?

What do you think?

Would it be even possible to use no snubber at all because my MOSFET can handle up to 650V?

I would be really thankful for a Solution.

With best regards

Daniel

University of Stuttgart.