Hi TI experts,

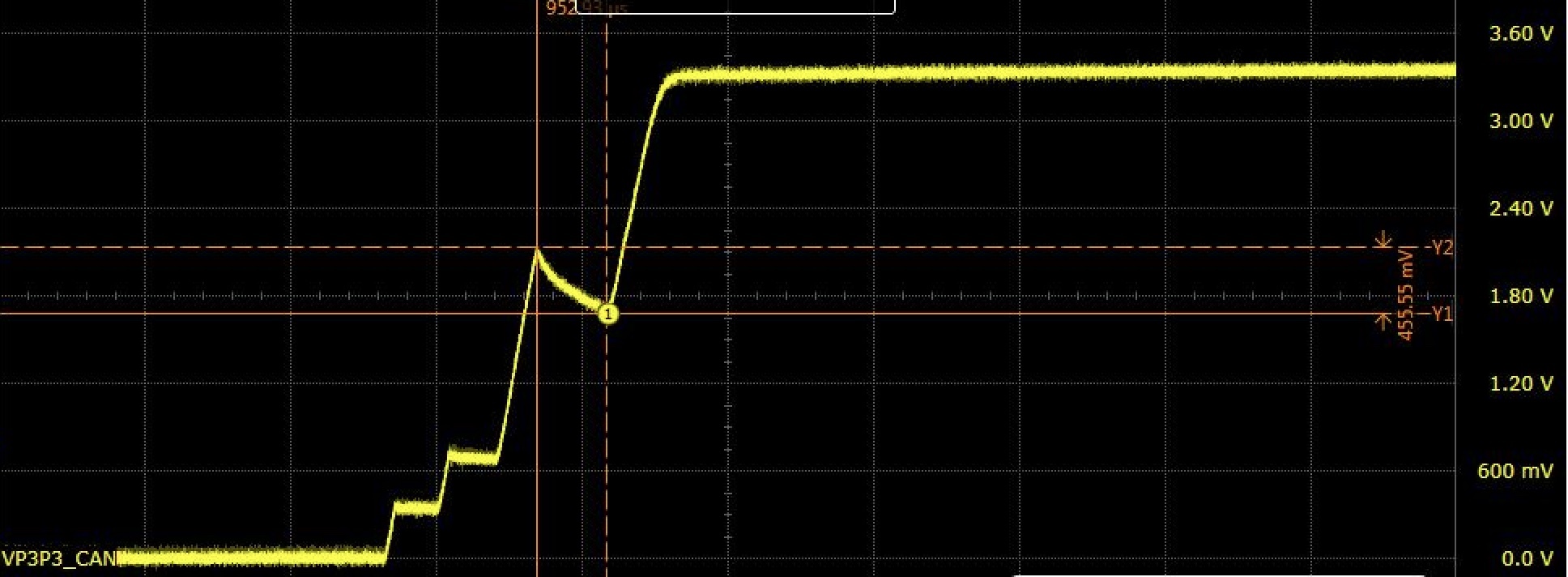

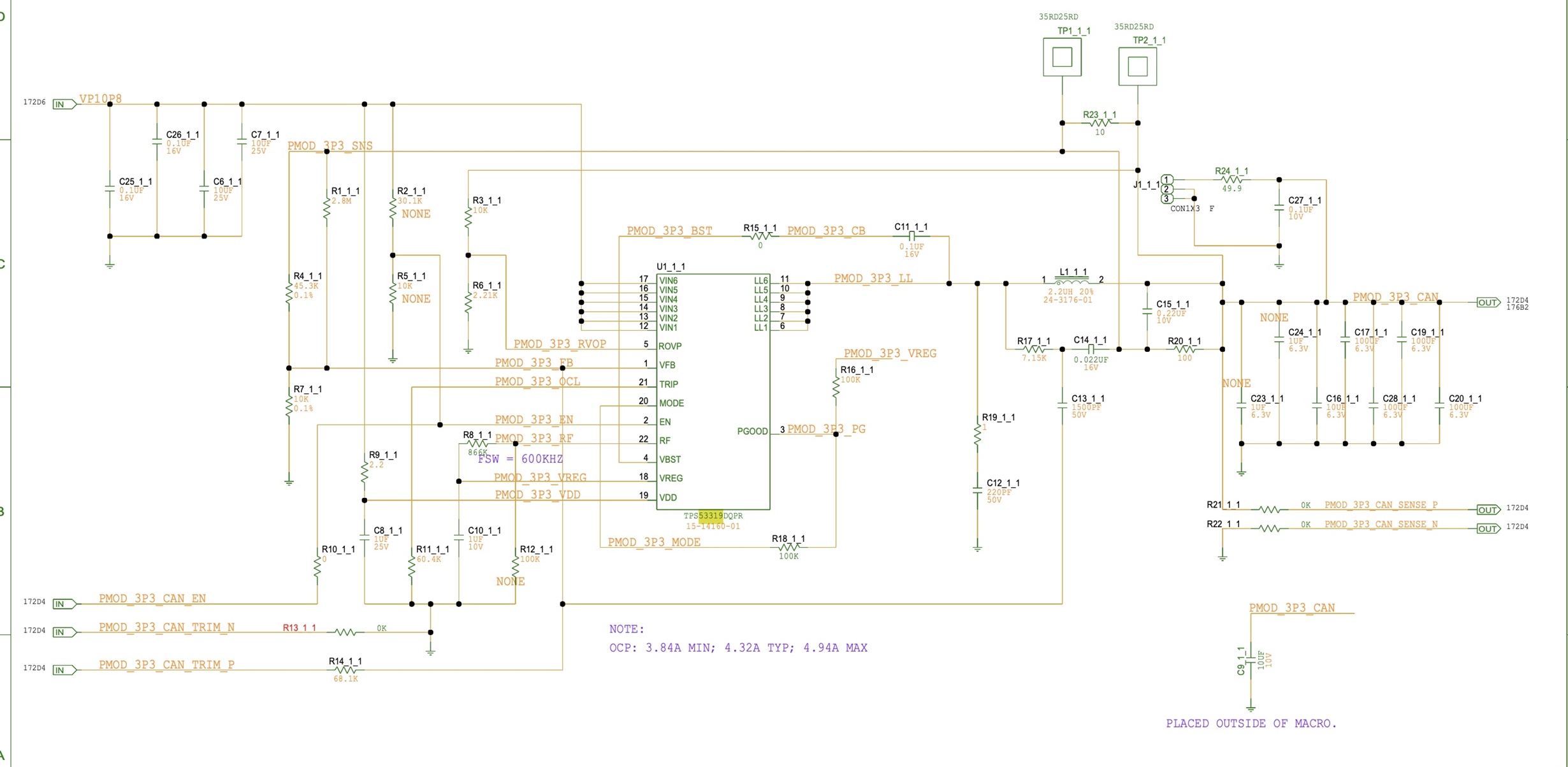

i used TPS53319 to convert 11V to 3.3V/10A. Tested transient/stability/ripple/startup/shutdown waveforms at 25C, all looks good.

But at 45C, observed 3.3V voltage glitches at ramping up. Planing to probe EN/DIDT/VOUT waveforms at 45C for analysis, but apart from that, is there anything else we can check? Or any idea about this issue?

Please advise.

Thanks.