Other Parts Discussed in Thread: BQ76952, BQSTUDIO, BQ40Z50, BQ4050, , EV2400, BQ76942, BQ79616-Q1

Hi team TI

I am using the BQ76952 evboard for 4s LiPo4 cells and controlling the cycling between loads and a power supply using a single board computer ( host processor using i2C ). I have faced the following issues :

1. Even tho I have set COV and CUV threshold to 4V and 2.5V respectively, the charging doesn't occur above 3.4-3.5V and OCC ( over current during charging) register goes high even tho I have set 3A on my power supply which is 0.5C of the battery pack. Can I know how can I allow the charging to take place at higher current values like 4A without having the OCC error to show up. here I also want to know the OCC register settings which show 4mV as default for the current sense resistor, what should be its value in order for me to allow higher currents to pass through the board ( i.e. greater than 3A and less than 6A).

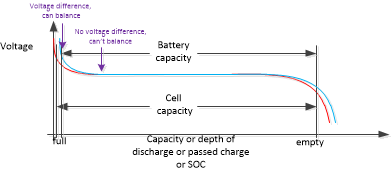

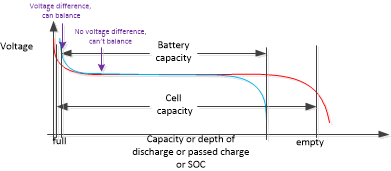

2. this board as said in the manual can have a max balancing current of 65mA so acc. to this how long will it take for the balancing to fully complete as the cell balancing takes too long and I am not able to have a balanced voltage between these 4 cells. during the charging cycle, even tho I have set balancing to occur after 3V. should I lower this value more but then balancing will take quite a while. (right now I have set my supply to be 14.4V at 3A) but the pack never charges to this since one of the cells reaches the limit while other cells are still behind it. for eg cell 1 reaches 3.5 while cell 2 and cell3 are sitting at 3.4V and 3.3V. Can you guide me with what mistake I might be doing in the cell balancing settings?

3. This board uses a series combination of FETs for charging and discharging, is it possible to have both FET's closed ?( both charging and discharging to happen simultaneously). as I want to make my own 150A LiP04 (16s- 48V) system using your battery monitor and balancer ICs from this model but then with the higher current path, what would be your recommendation on whether I should be using two contactors or series of anti-parallel Mosfets to carry higher currents out of the board. Of course, I will be developing my own schematics for the PCB design but I want to be first sure about the changes I should consider while upgrading your product for higher current capability. using MOSFETs does give losses (Rdson) but are they significant compared to having contactors ?

Sorry for the long query but I am really confused with these doubts, hope to get the response soon :)

Kind Regards

Bilal