Other Parts Discussed in Thread: TPS565208, TPS565201, TPS566231, TPS566238

Hi All,

I have a question about TPS54425.

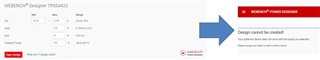

I tried the simulation with webench under the following conditions, but it didn't work.

Does the following condition not work?

VIN = 5V (± 5%)

VOUT = 3.3V

IOUT = 4A

If it doesn't work, please tell me the reason.

Best Regards,

Ishiwata