Other Parts Discussed in Thread: TPS3808

Hi,

The following supervisors control the reset pin of our System on a Chip:

- TPS3808G01DBVT

- TPS3808G12DBVT

- TPS3808G15DBVT

- TPS3808G18DBVT

- TPS3808G33DBVT

- TPS3808G50DBVT

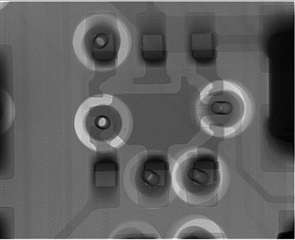

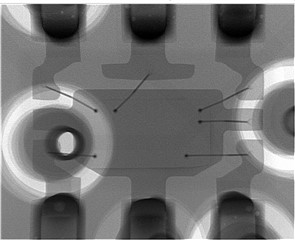

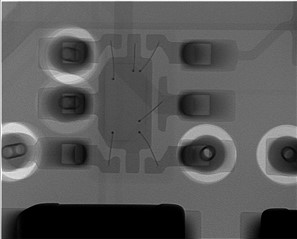

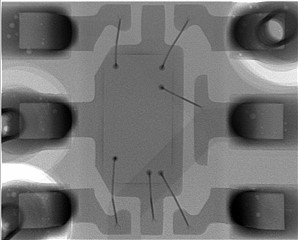

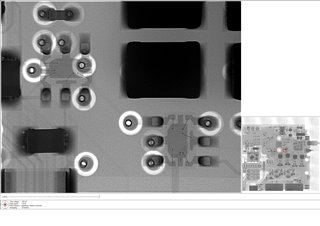

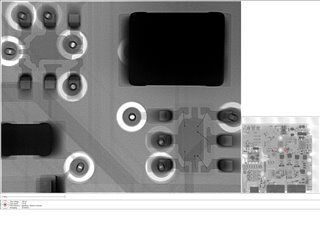

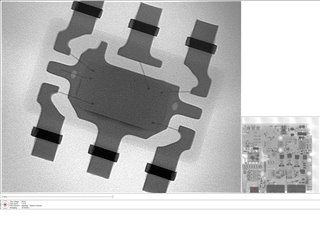

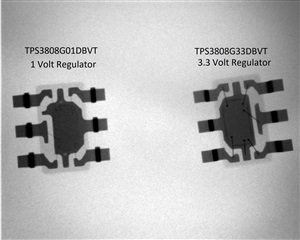

We have been having issues with our SoC powering down during a high-impact shock event on the drawer we have these supervisors installed. When x-raying the components to see if there was any damage sustained to the components or nearby traces we noticed something odd with the internal bond wires. We were able to easily make out the bond wires for the 'G12' supervisor to the 'G50' supervisor. However, the bond wires for the 'G01' were extremely difficult to see at the same magnification level as the others. We needed to zoom in much further to even barely make out the bond wires in the 'G01' I know the 'G01' is slightly different from the other supervisors since it is adjustable, however it seems odd that the bond wires would be so much thinner. Please let me know your thoughts on this.

Thanks,

Ryan Savage

U49 is TPS3808G01DBVEVM

U51 is TPS3808G33DBVEVM