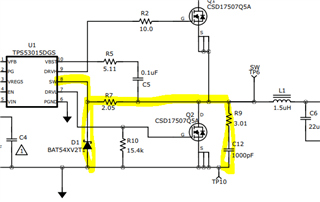

My customer is trying to reduce component count on TPS53015 design. Are both the zener + Rclamp and snubber circuit necessary on the switch node? Or is one sufficient for reducing SW node ringing - which is recommended? Our application is 12V-->3.3Vo @ 8A max