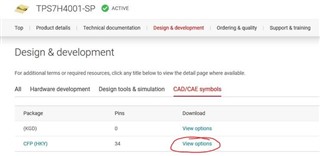

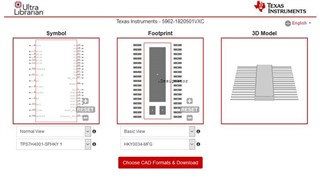

Could TI please provide guidance for how to trim/form the leads of ceramic devices and provide the PCB footprints so we can integrate into our system design?

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.