Dear All,

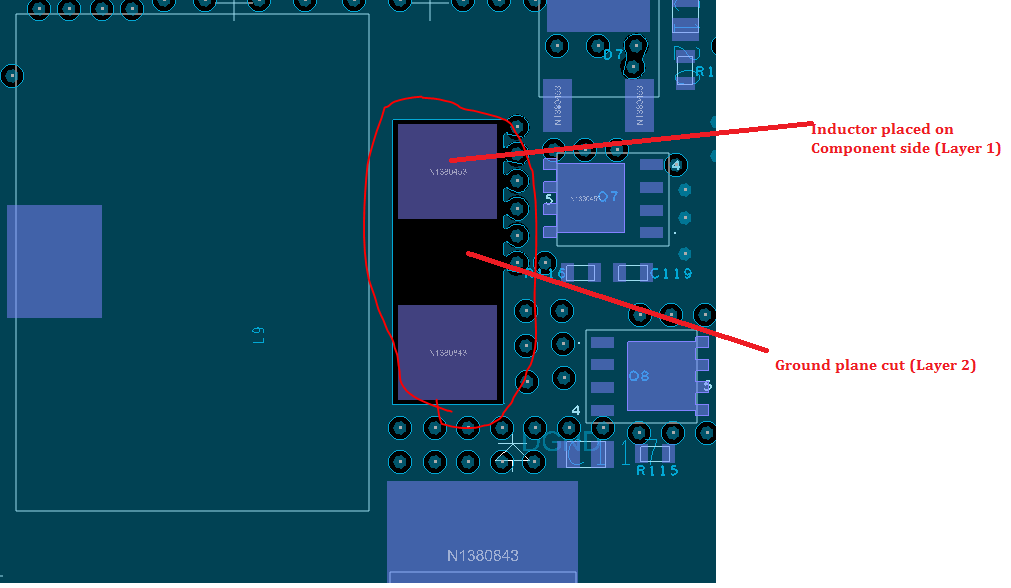

We are following practice of ground plane cut below power inductor used in DC/DC converter to avoid EMI issues.

The reason behind this is to avoid coupling of field with ground plane and induced noise voltages in ground plane.

But there are some different opinions which also seems logical that any cut or slot in ground plane could act as antenna because they disturb current return path.

Does anybody have explanation of which practice we should follow and when?

Thanks in advance for your help.

-Bipin