Other Parts Discussed in Thread: TPS5420, BQSTUDIO

Hi,

I have a small design with a GSM module and I use as power management the BQ25892 chip.

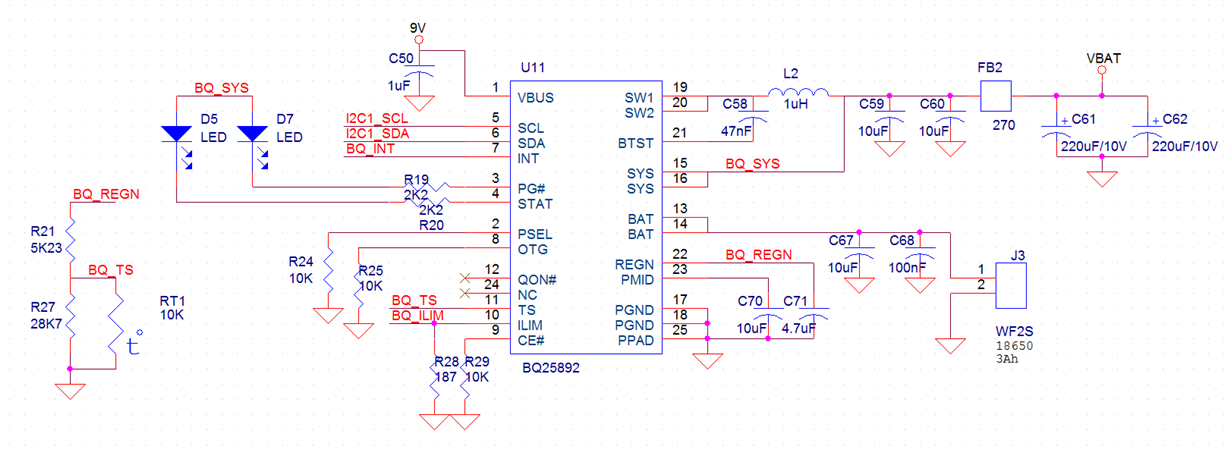

The design input voltage is regulated using a TPS5420 converter with the output set at 9V. BQ25892 is getting this 9V voltage as input voltage. The battery is a Li-ION 18650 3.7V, 3000mAh.

The GSM module is working with voltages between 3.4V and 4.4V. I need BQ25892 to have the SYS output voltage between 3.5V and 4.2V.

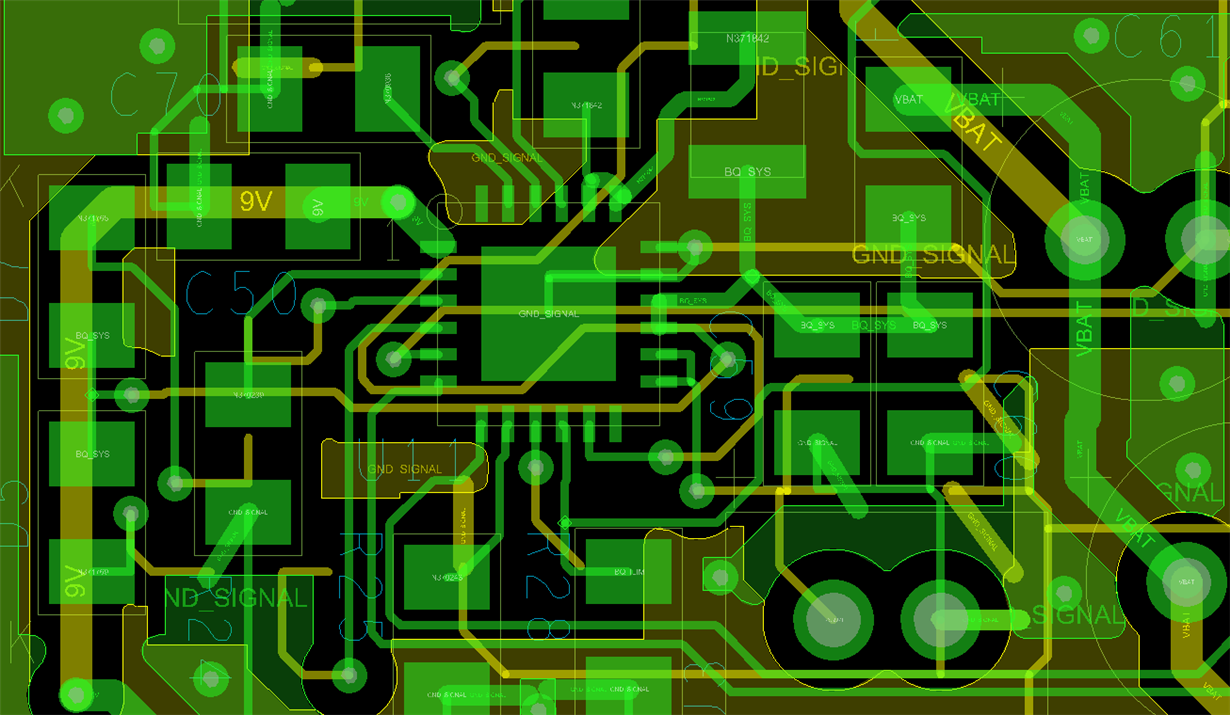

I'm using the following design for the battery manager:

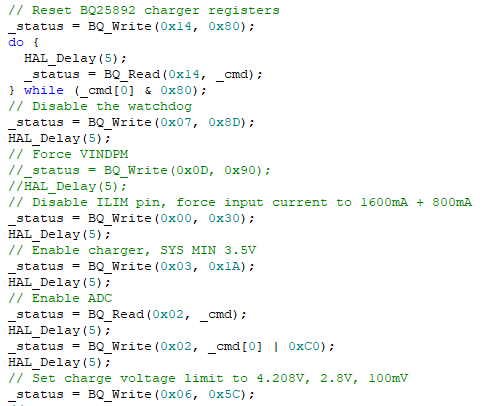

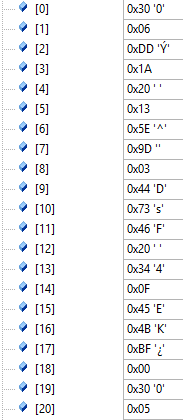

The initialization sequence that I'm using for BQ setup is:

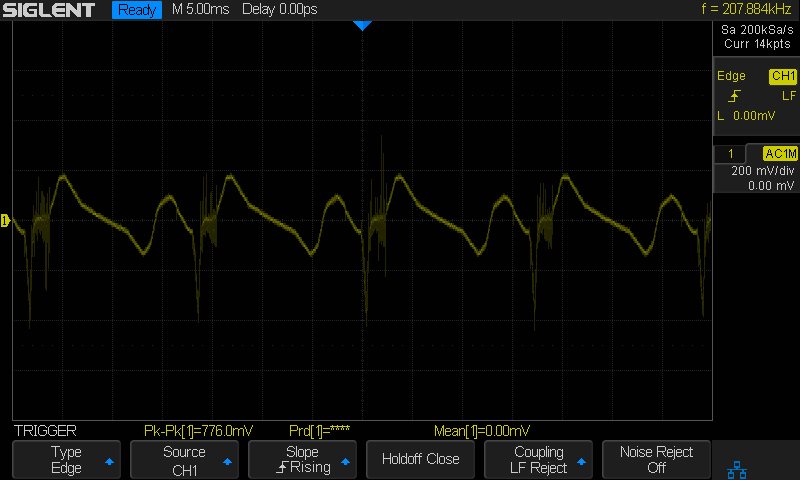

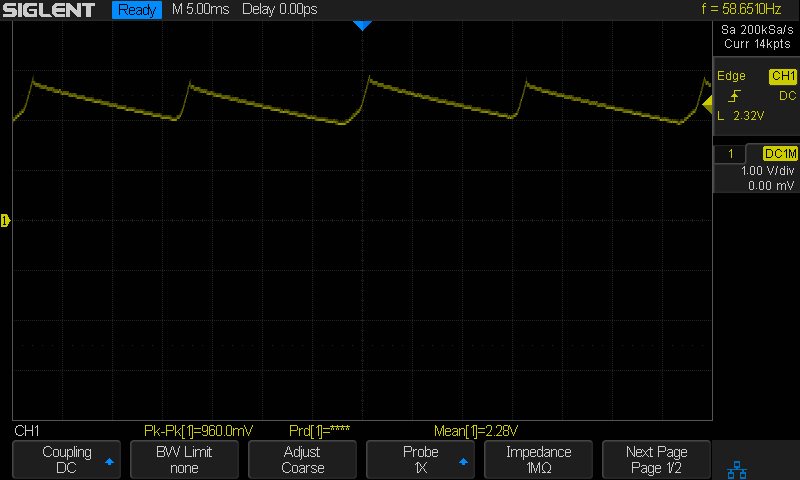

After countless trials I came up with the above sequence, but the results are not quite good. The charging current is settled after a second o so at ~200mA. First, the charging current reaches ~500mA, but is drops immediately.

Another problem is that if the battery voltage drops to low ( < 3.8V) the charging process will not start. Sometimes the BQ gets stuck at system startup (both STAT and PG LEDs are poorly lit) and the TPS5420 enters in protection mode. Also, I guess when the charging process is about to be completed, the STAT led is blinking very fast and the voltage on the battery is jumping very fast between different values (4.01V - 4.15V).

I'm trying to figure out how the initialization sequence can be done right, any advices are more than welcome!

Bet regards,

Cristian