Part Number: BQ20Z45

Hello guys,

I did check the DF subclasses mentioned above and have a few questions

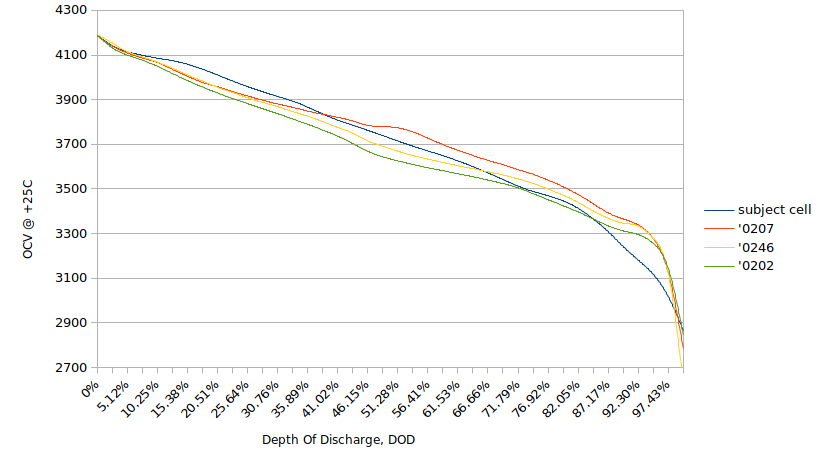

Sublcass 83. It seems it contains single cell OCV per remaining capacity dependency. It is fine, but. Why this dependency

ends at approx. 3V0? Many (well, some of) cells have a mention of 2V5 cutoff voltage. So what does happen if we have

termination voltage set to 2V5 while main chemistry table ends at 3V0?

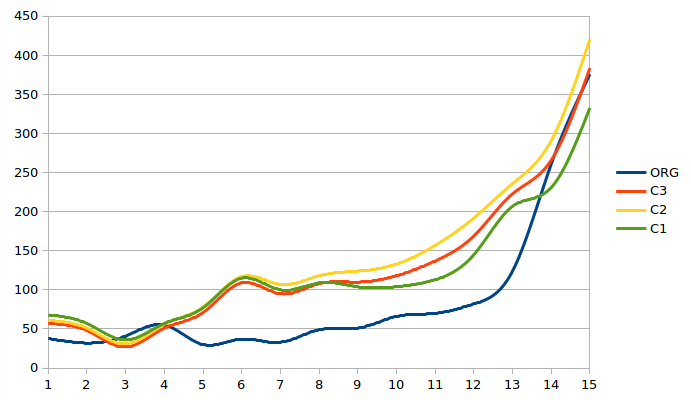

Next, the associated tables 84 (40 points), 85-86 (15 points each), what is their intention? What data is stored there?

And, what is more important, are these tabes are used at all (f/w version 1.05)? I am checking the firmware, but cannot find any

traces of their usage. Well, investigated it not in full yet, but still.

So if possible, could you pls shed a few light on this?

Thanks!