Part Number: TL494

Other Parts Discussed in Thread: UCC27517

Dear experts,

My customer is developing a boost power supply with TL494.Now they find the boost output increase and need TI's help.

-

Application background:

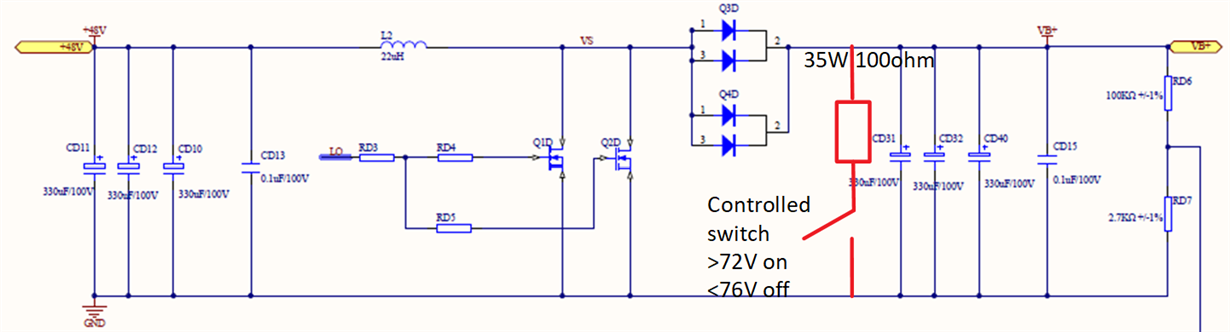

48Vin 72Vout 1.5kW boost power supply for motor driver. Their system is Boost (TL494+gate driver UCC27517) + Three-phase inverter bridge + synchronous motor.

-

Problem description:

Based on end customer’s need, the motor need to operate under the condition of deceleration and over rated speed. Due to these conditions, motor will generate energy flows into pre-stage boost circuit, result in boost Vout spike. During this Vout spike condition, TL494 shut down the FET and can’t control the output voltage.

|

Boost rated output voltage |

Output under motor deceleration condition |

Output under motor over rated speed condition |

|

72V |

80-90V last for 1-2s |

90+V last for 10s |

-

Ask for suggestions:

1. Add energy absorption circuit (3*330uF+ 35W 100) could decrease the output spike, but the cement resistance is over 90 degree of centigrade. So is the absorption circuit parameter configuration is not suitable? Or is there any better solution to solve the energy?

2. Will synchronous rectification boost circuit can solve this problem? But when down-side FET ‘s duty cycle is 0, will bootstrap driver ability be affected and can’t turn on the upper-side FET? Is there better solution to solve this kind of motor driver problem?