We've noticed that the Rtheta-JB is 29.1C/W for this device TPS7A9201DSK. Comparing to the TPS7A7100RGT which has an RthetaJB of 17.2C/W

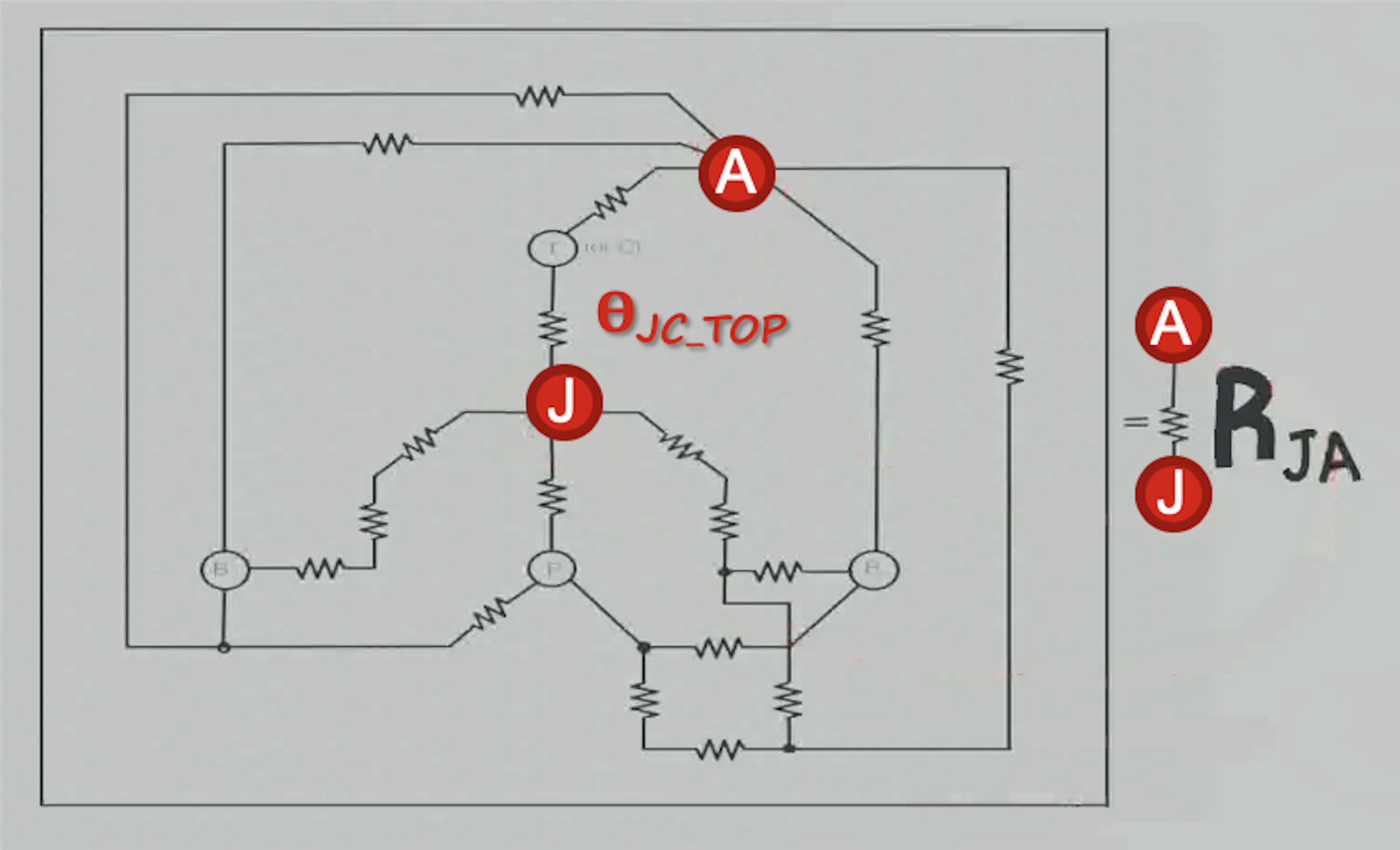

Why are the JB thermal resistances so dramatically different given the Rtheta JC specs are about the same - is this correct? Are there two different constructions inside?