Hello!

We are using the BQ24195 chip within a powerbank application.

With loads below 1.7A the chip works correctly, but if the load is higher, I meet with a voltage drop after a few minutes of work. The temperature of the chip reaches 85 degrees.

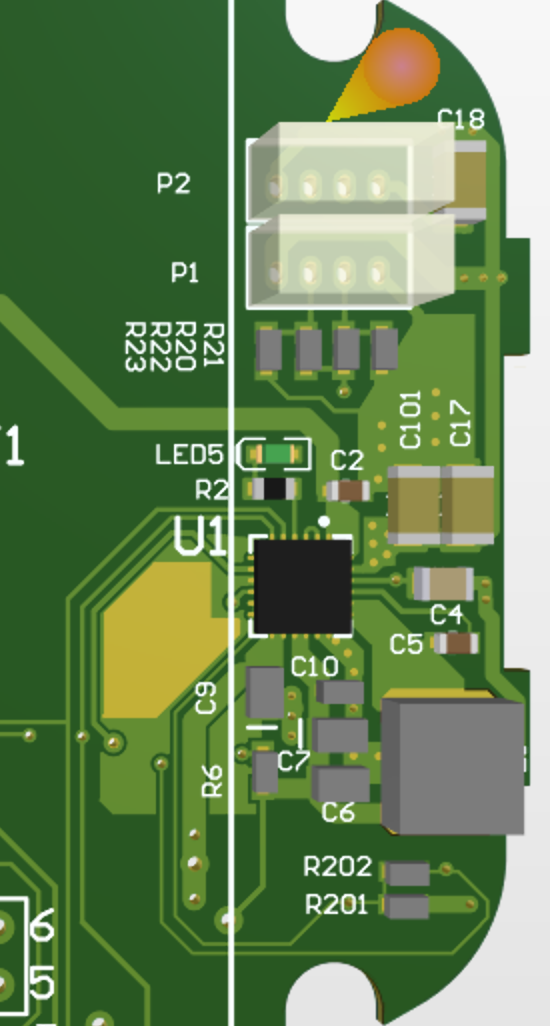

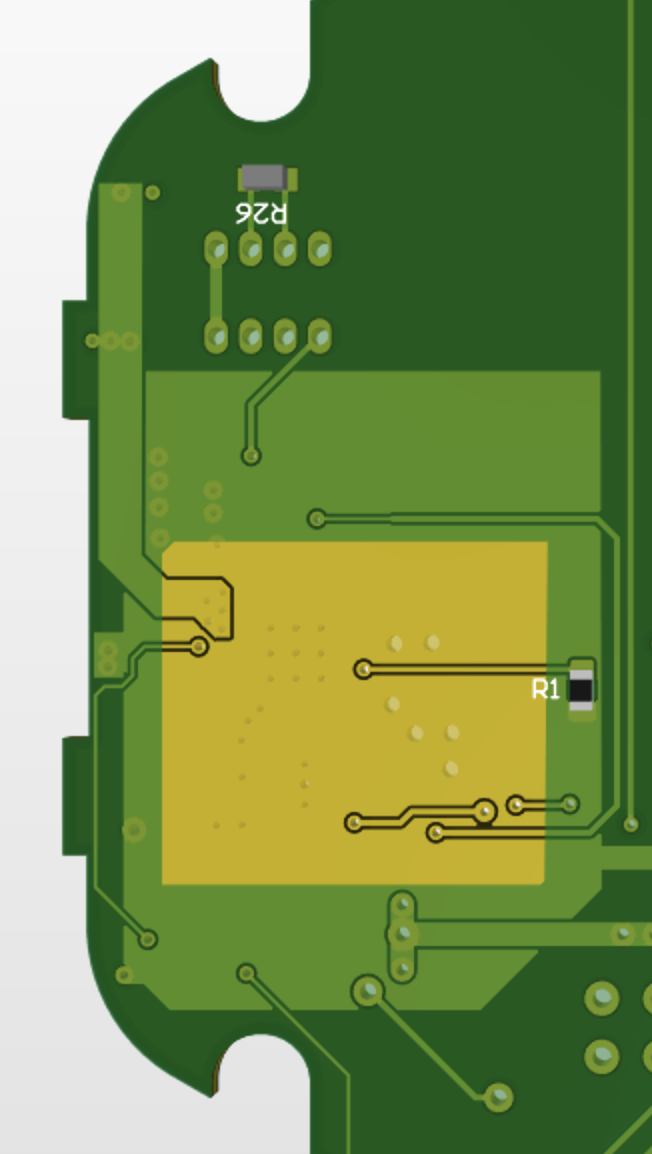

What role does the size of the PCB board play in overheating? Also, we have vias and thermal pad in our design, but we still face the problem of overheating. We've made a space with an open ground area on the top and bottom layers of the PCB to dissipate heat, which has slightly improved the situation.

I have an Evaluation Board on my hands, but I don't see this much heat under heavy loads.

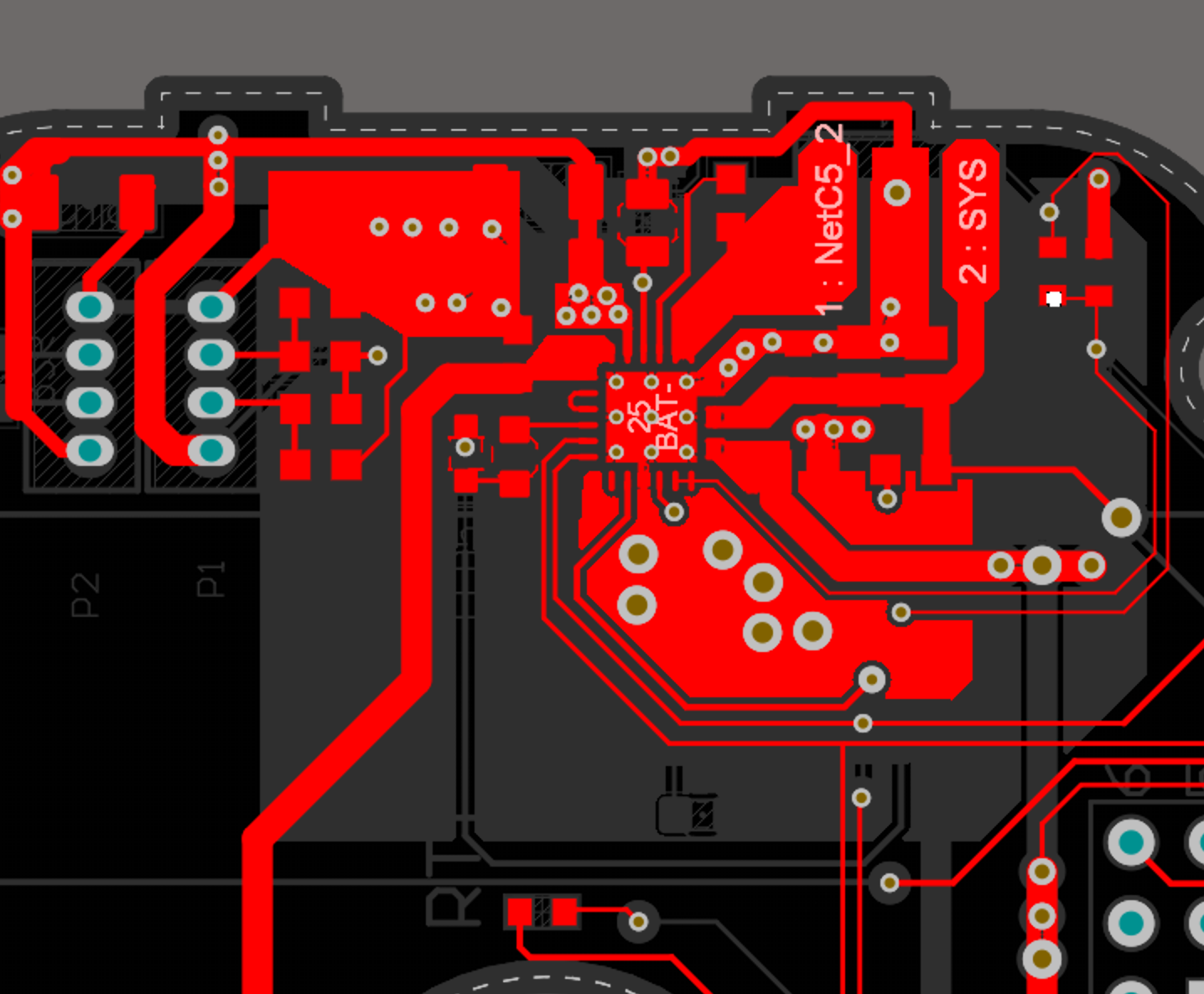

I've attached the top layer of our application, maybe you'll have some tips on how to improve the situation.

Best Regards!