The LMZ36002 datasheet does not specify the input current for pin INH. What is this accross the temperature range?

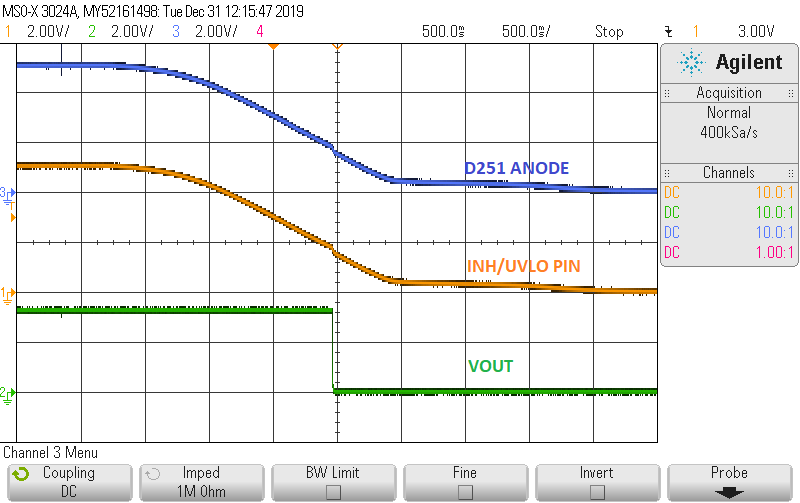

Our circuit employing the LMZ36002 stops working above ~50DegC. This has been traced to the INH pin which draws more current as the ambient temperature rises. Consequently, our (current limited) enable signal voltage drops below the 2.8V threshold. What current does the INH pin expect?