Hi Team,

One of my customer is facing the challenge in cold join.

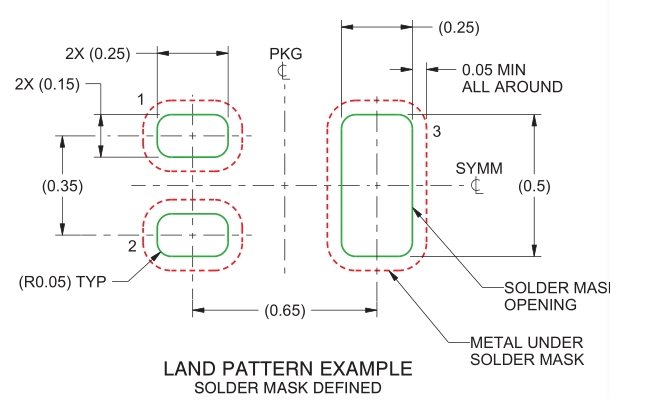

At first, pads designed according to the manufacturer's recommendation.However, tin beads and cold joint problems occurs after the patch.

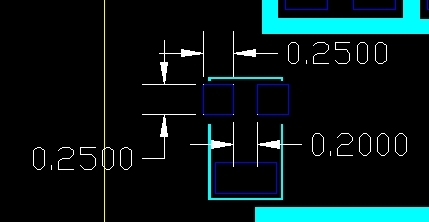

then change the design as follow:

and still have problem in cold joint after a number of steel mesh optimization in SMT plant.

Can you give us some suggestion in this case?

How can we solve this problem?