Hi, I have a PCB design that successfully utilises the TPS59124 (1000's of operational boards), however we have found that a few boards that were kept in storage for 12 months no longer power up successfully.

The regulator produces the correct voltage, but the PG line does not go high. Sometimes just one half of the regulator is affected, sometimes both sides are affected.

We baked the problem boards prior to reworking them (60 deg), and noticed that baking alone cured the problem.

Could the characteristics of the device change slightly with moisture level?

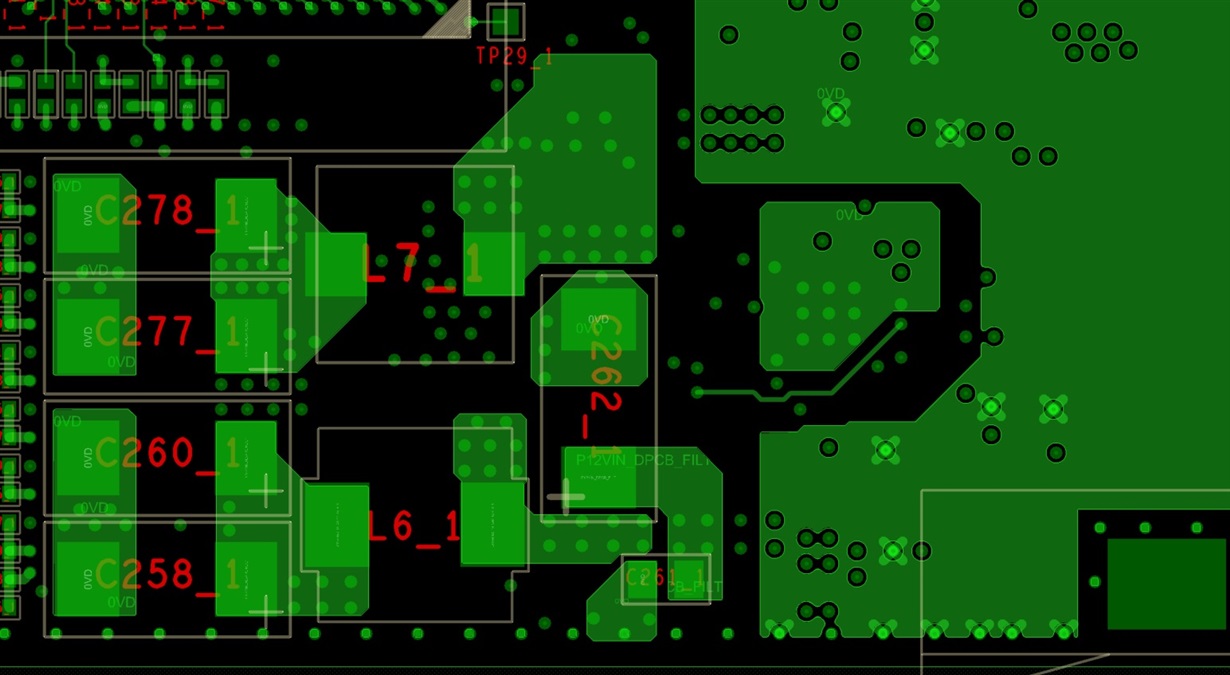

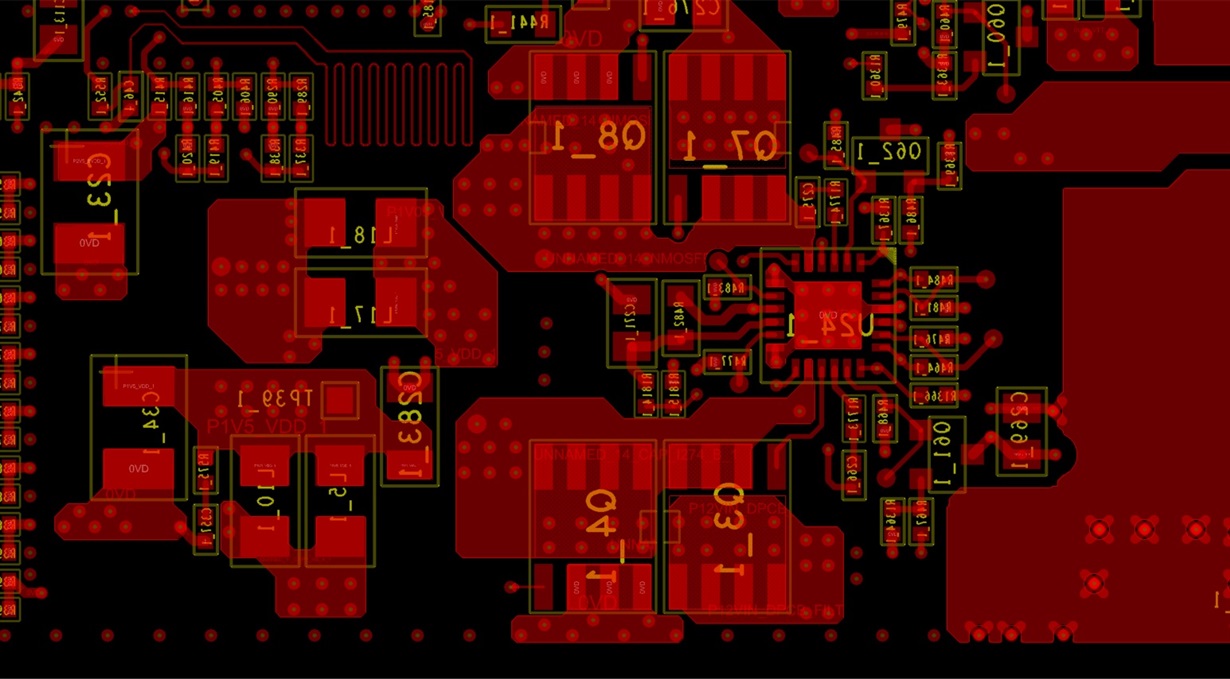

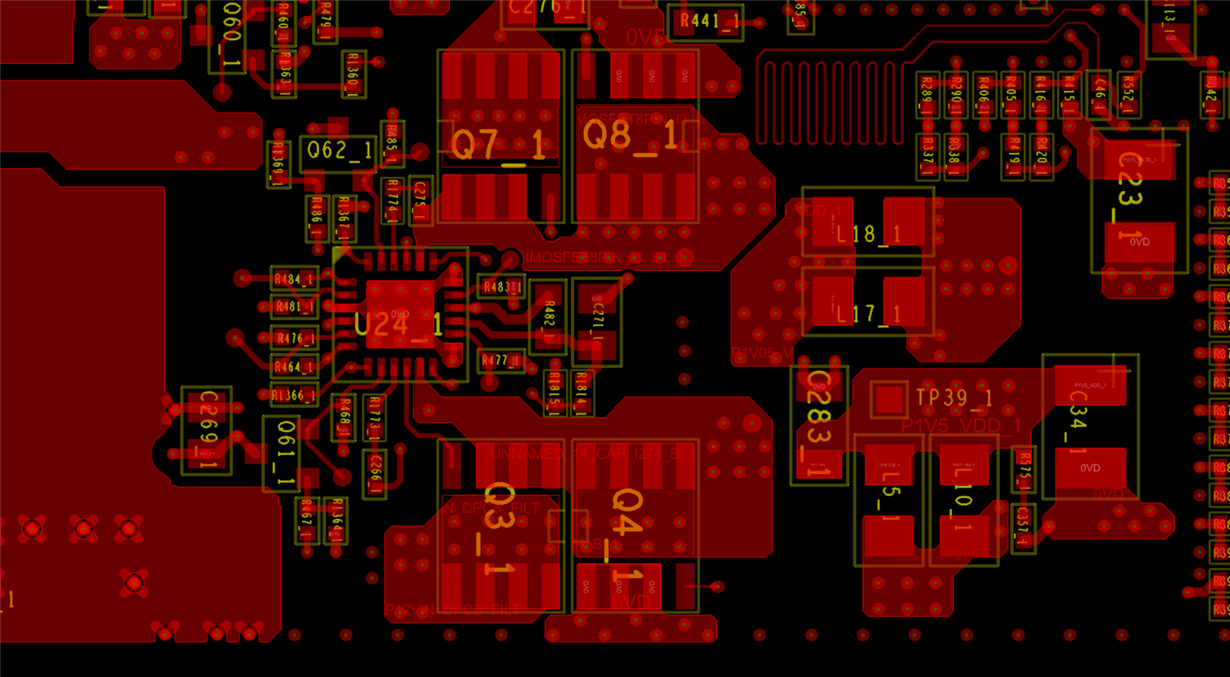

I'm wondering if there is a weakness in our layout, and a change in device characteristic tips them over the edge?

Any suggestions would be greatly appreciated.