Other Parts Discussed in Thread: UCC28950, UCC5350, UCC21520, UCC21225A, TIDA-00446

Hi team ,

I'm looking at UCC23313 gate driver part and another manufacturers parts for drive the mosfet.

How can I understand what the frequency range of the optocoupler is?

For example what does

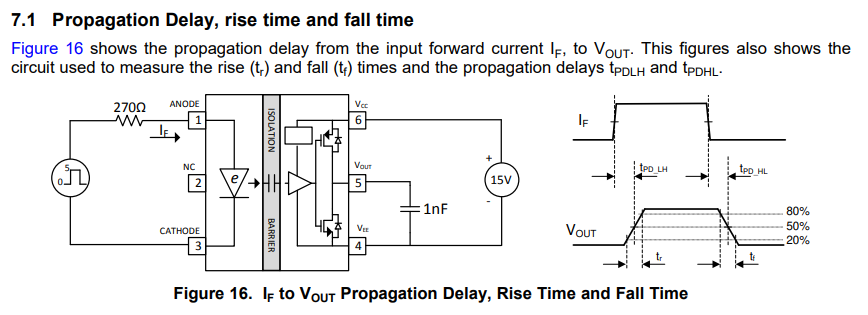

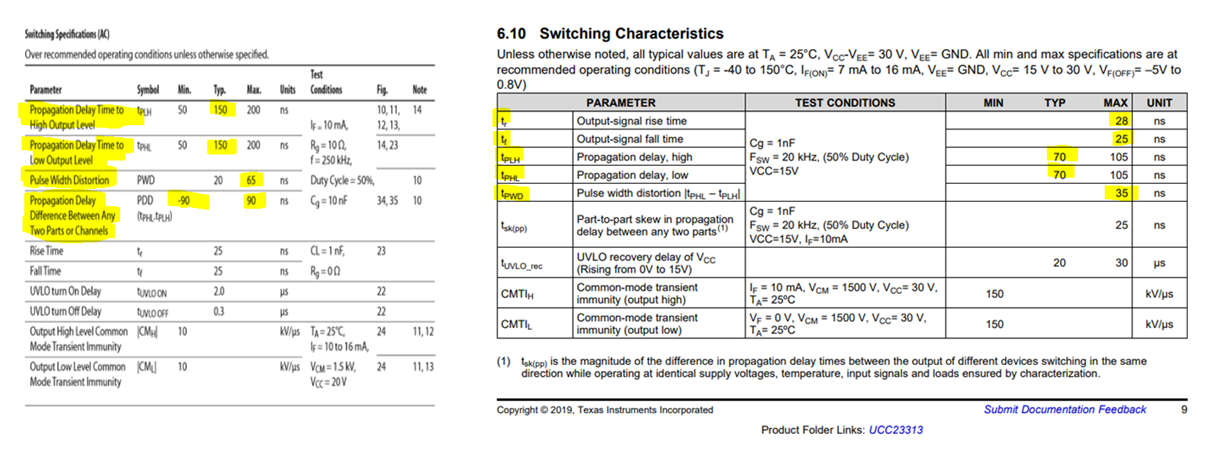

- propagation delay

- part-to-part delay matching

- pulse width distortion

terms mean?

And there is a figure below of the HCPL3180 gate drivers IC ,

So can this IC & the UCC23313 work in 150kHz %90 duty cylce?

Best Regards