Other Parts Discussed in Thread: UCC21540A

I have designed a PMSM controller, everything is working fine.

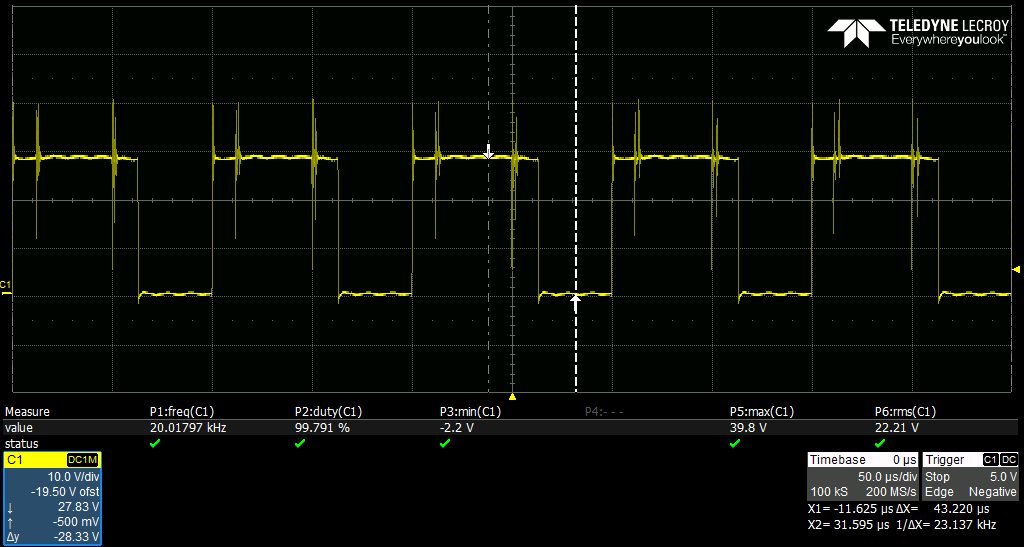

But at phase voltages, there are some ringings.

What can cause to this problem?

Mosfet drivers UCC21520 parallel 2 channel for each mosfets, i am driving all mosfets with discrete mosfet drivers with isolated 12V DC-DC converter.

I have increased and decreased gate resistors to 0R-10R range, nothing changed.

I have also RCD snubbers, 1R+47nF capacitors to mosfets.

Fsw=10kHz

Bus voltage is very smooth, no ringing. Bus capacitors are 5x6800uF Al-El Capacitors and 20x22uF ceramic capacitors.

At 100 rpm there is not ringing at phase voltages, ringing is increasing by motor speed increase. Phase current around 15A.

Mosfets has large Qgs 375nC, 2 parallel mosfets.

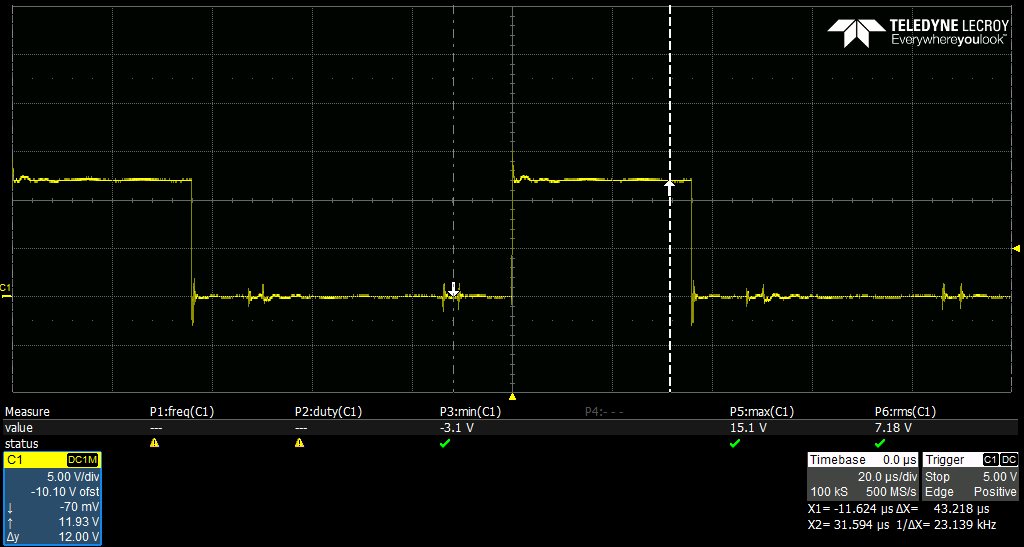

this is low side Vgs voltage, small ringing can seen in the gate voltage, but at high side there is no ringing.