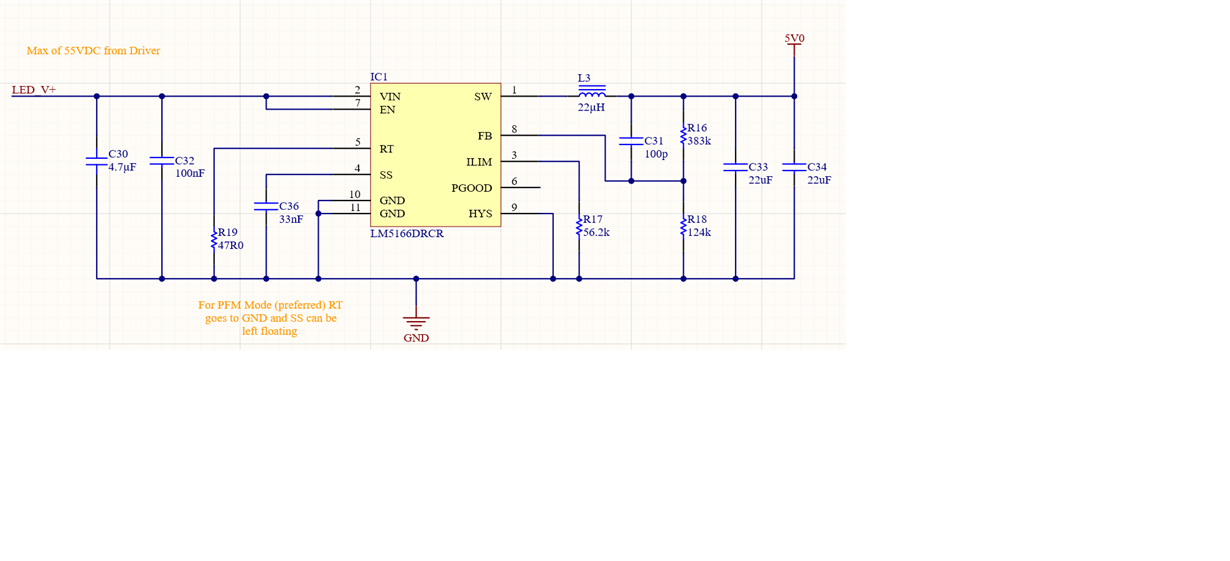

Other Parts Discussed in Thread: LM5166, LMR16006

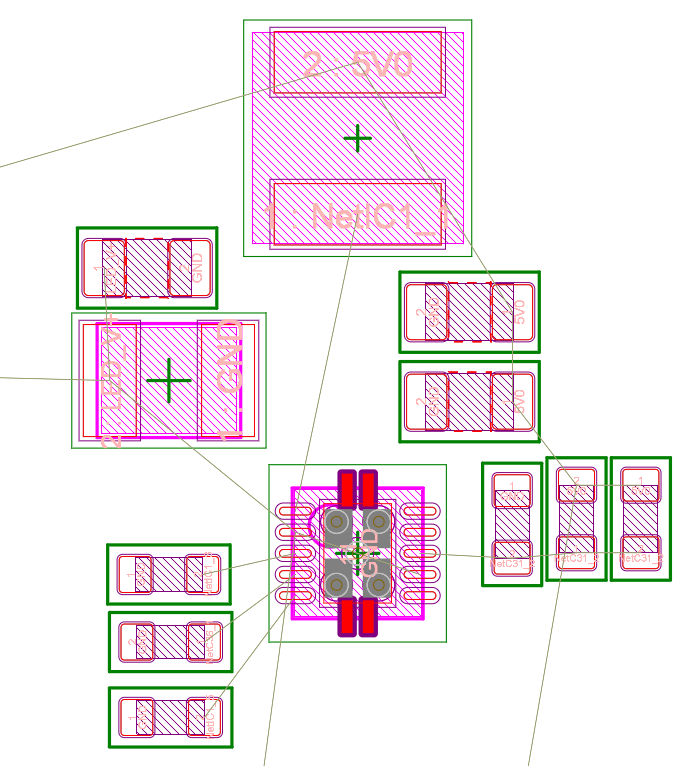

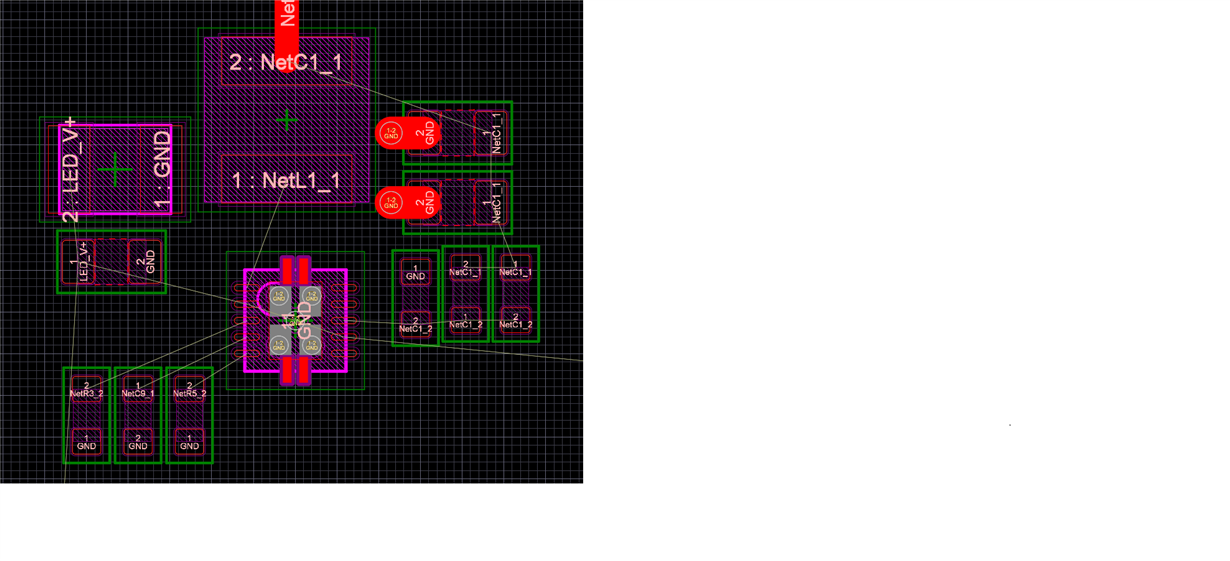

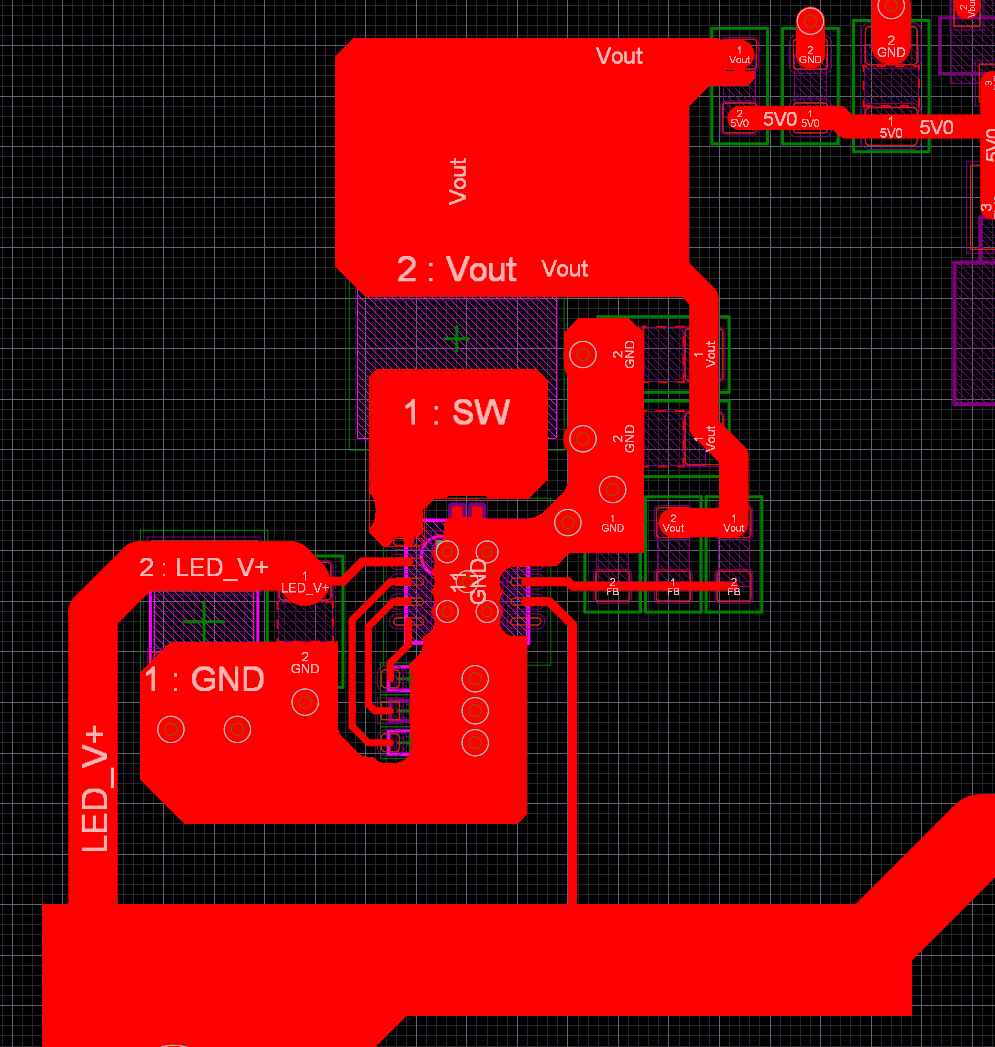

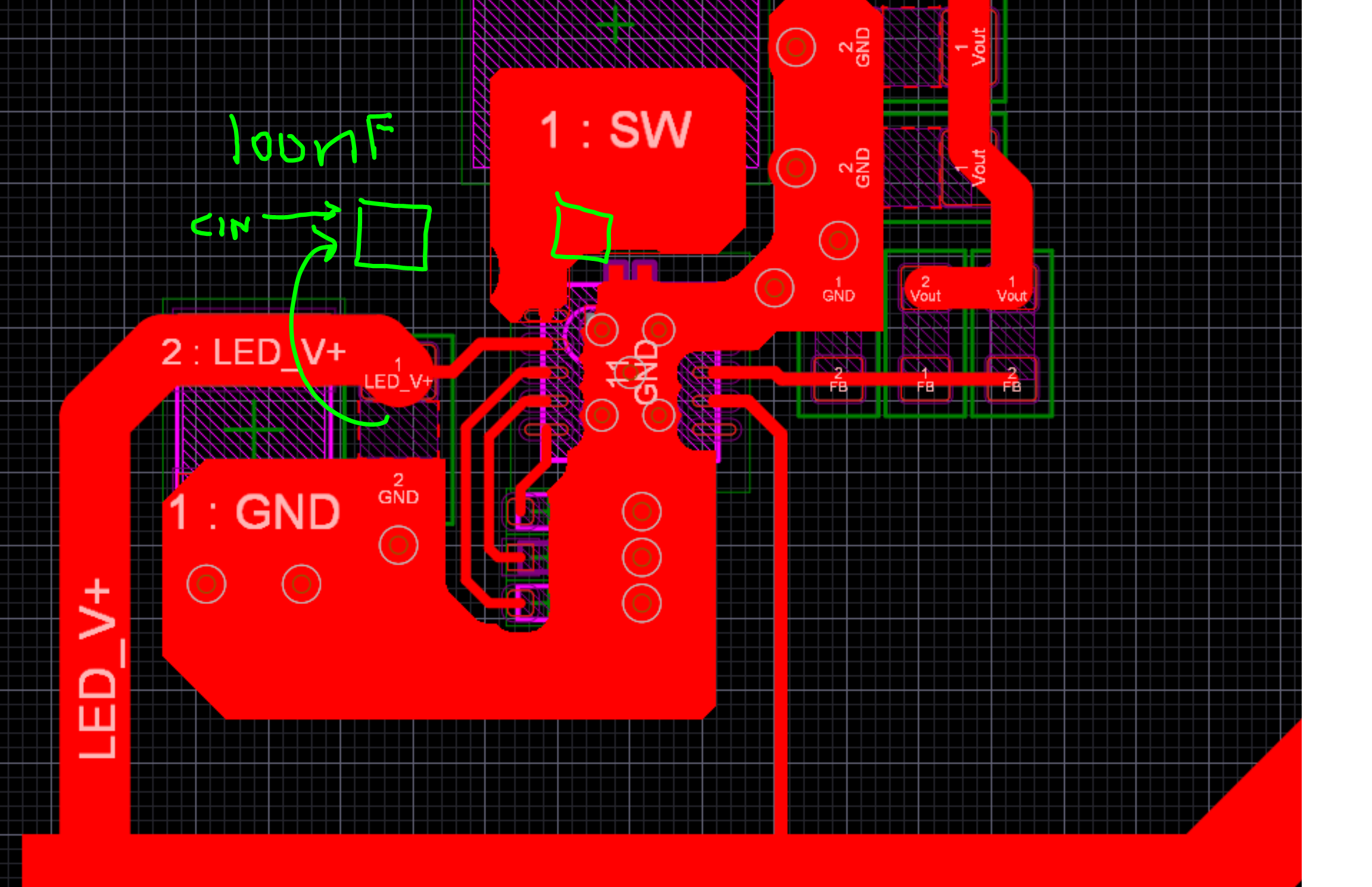

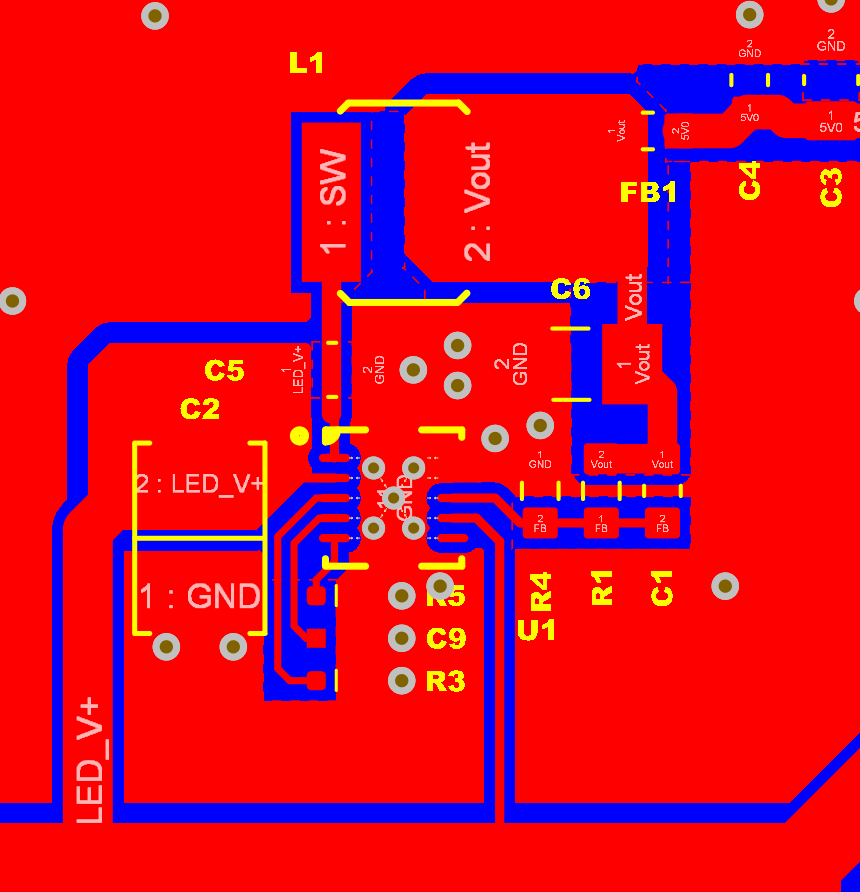

I've got a situation where my input parameters are fighting the design criteria. I know from reading that I actually need to use the LMR16006X part to have the lower 700kHz switching frequency. But with my high input voltage and low output current I keep coming up with very high and large inductors. I read in 1 post that I could "ignore" the web bench calculations and use a smaller inductor and compensate for the increase output ripple with more capacitance.

My mechanical area is restricted so I'm trying to minimize the area as much as possible. I looked at a lot of different switchers and the LMR16006X looks like the best fit but maybe someone knows of another part that might be better (I originally designed in the LM5009MM). The efficiency of the LMR16006X looks much better so hopefully I can just use a smaller inductor?