Hi

We are running thermal analysis on a board with multiple LDO's and other components.

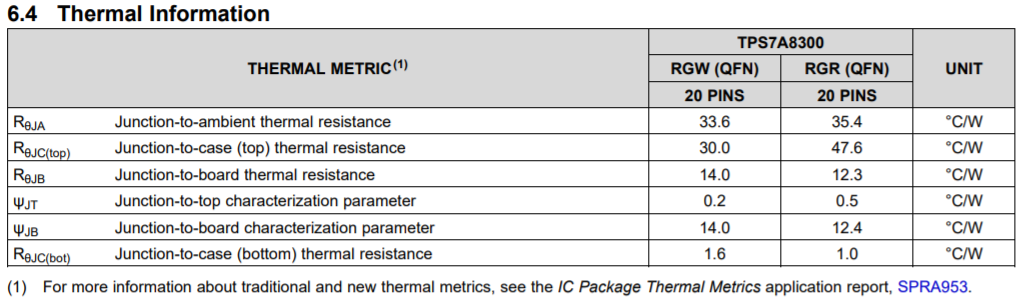

We are not sure which metric to use when trying to calculate the TPS7A8300 junction temperature. The application note SPRA953 is not clear.

According to the thermal simulation, we know the PCB temperature on the ground exposed pad footprint just below the LDO. Which metric should we use in order to calculate the junction temp, junction to case or junction to board?

Thanks