hello,

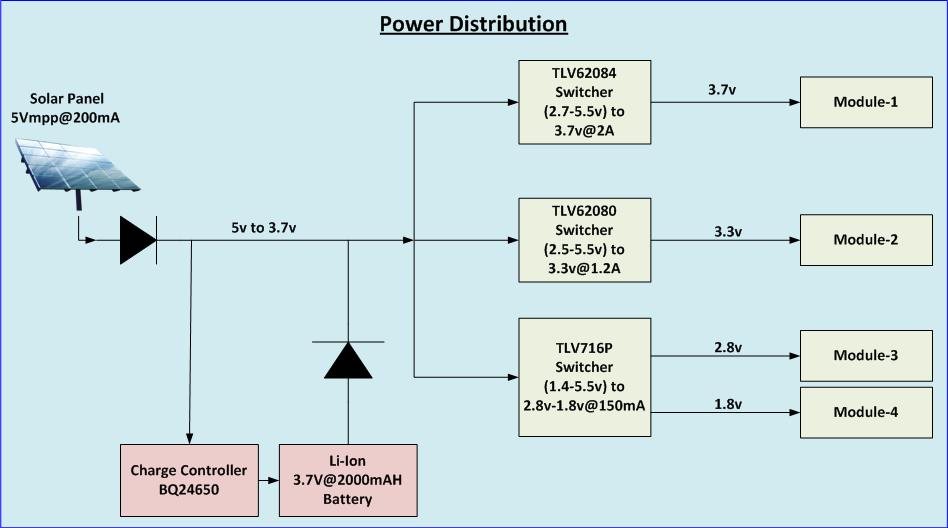

We are working iOT based design with solar power design.

i require MPPT solar charge controller which is suitable for my power consumption requirement.

my device power consumption requirement is 3V@700mA

and also connected 4.2@2000mah battery for battery back up

you have better solution please suggested us suitable MPPT based solar charge controller for our system power consumption.