Other Parts Discussed in Thread: CSD17578Q3A

I have been doing the design with this buck-boost and found out that Webench Power Designer is giving false values or datasheet equations are not correct.

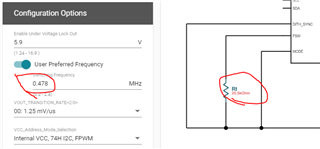

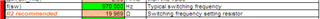

For example when I calculate resistor for 2MHz operation I get value of 9.6kohm and Webench states 9.768k is for ~1MHz. Also what I find annoying with Webench is that even if I manually enter the wanted frequency the tool will automatically change it to whatever it wants.

Could I get an excel calculator that I can refer to and be sure that everything will be correct when I put all the components in to the schematics.