Hi team,

the customer have a question:

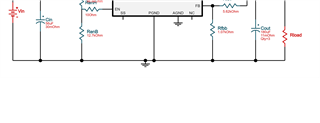

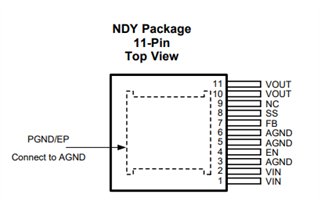

LMZ13608TZE/NOPB.

The product was produced using the circuit diagram and product that you advised me.

Shorts occur at pins 6 and 7.

Please check what is the cause of the short circuit.

At our factory, we doubt whether the product is defective. :( Is it possible that it is defective? I can send you probme parts samples from my board.

Best regards,