Other Parts Discussed in Thread: BQ24040, ALLIGATOR, TPS62740

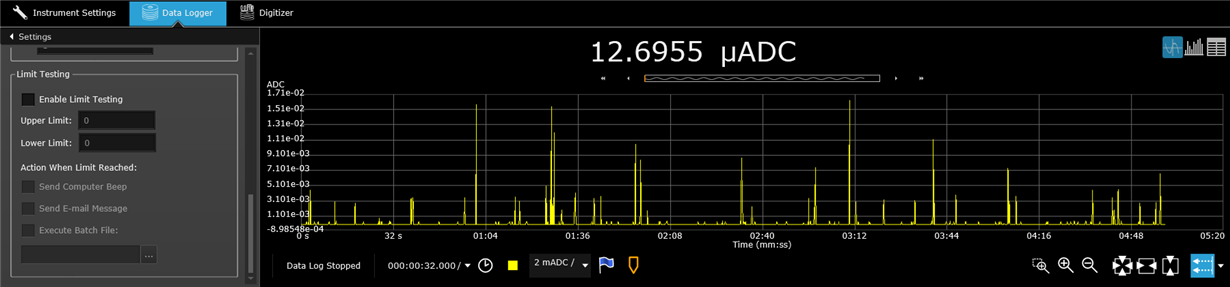

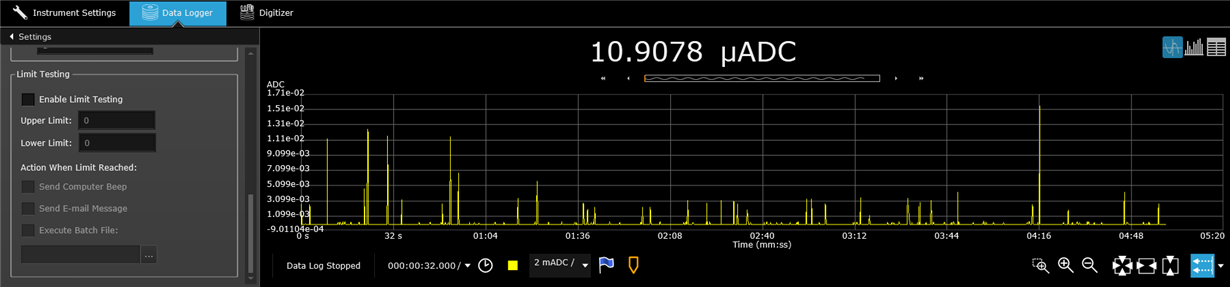

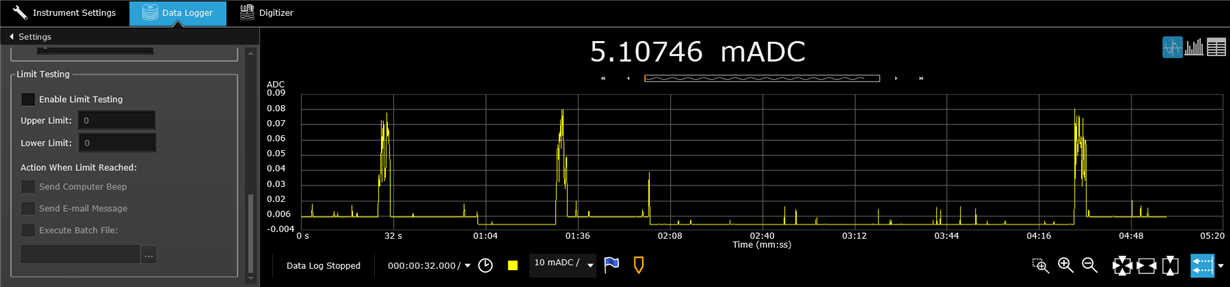

I have a product where we're using the LM3671-ADJ. I'm attaching my circuit but the part functions properly except sometimes when our board goes to sleep I am measuring it pull ~5-6mA when it should be ~100uA.

While trying to debug if this was a hardware or a firmware issue I touched the board in the area of the feedback circuit and the current consumption dropped to the ~100uA level. I'm not 100% this has something to do with the LM3671 so I thought I'd post to see if anyone had any ideas. The board is only about 1" square so trying so isolate what is being touched is difficult but it definitely seems to be just the filter parts.

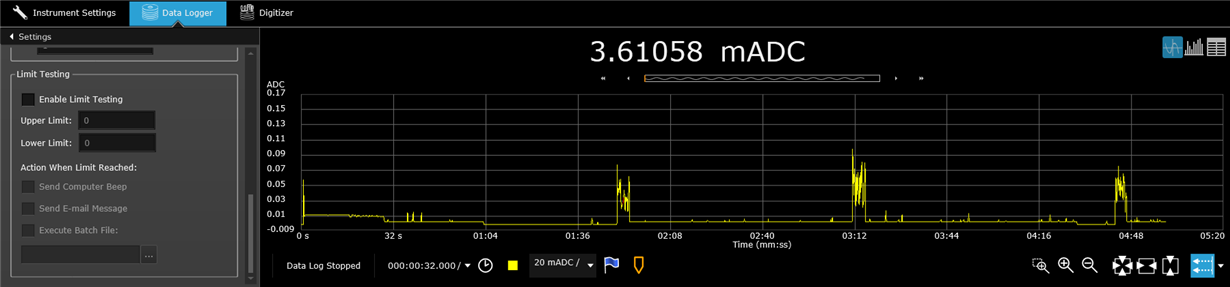

Another other thing I've uncovered is that if the board is pulling ~5-6mA and I touch the filter circuit I think the current consumption briefly increases before (~13mA) before dropping to ~100uA.

The last bit of information is that if I activate the motor for 1 sec and the board will settle back to the ~5-6mA mode and I can repeat this cycle of touching to bring the current down and activating the motor (which draws ~50mA) to get it to this 5-6mA mode.

Hopefully someone has some great ideas and it doesn't mean a new board layout since we've already started production.

Thanks,

George