Hello,

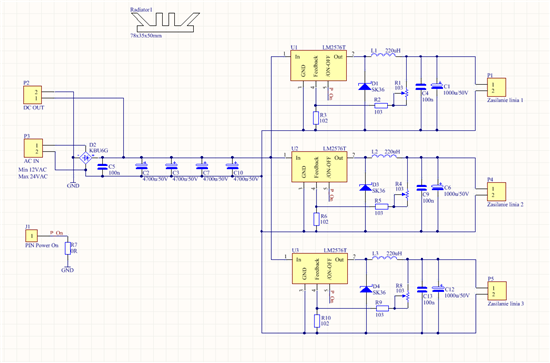

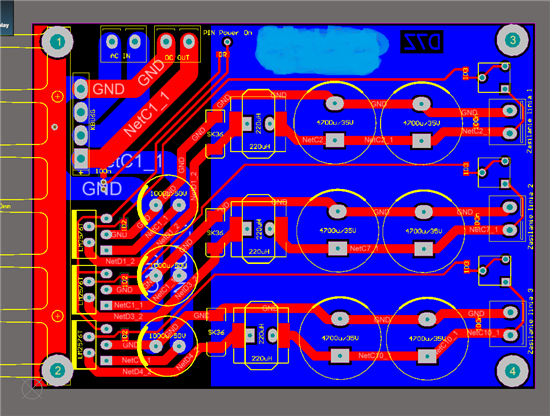

I've designed a power supply unit on LM2576-adj. There are 27V DC on the input and on the output I've set 20V. There are 3 LM2576's connected parallel after greatz bridge together with 3 electrolitic capacitors 4700u. On the output there is coil 220uH, 3A shottky diode and 1000u electrolitic capacitor. On the PCB there is 3 IC mounted to the heat sink.

The problem which I receive is that when I connect load with more than 1A current, one of the IC's which is in the middle gave me a noise on the otuput approx 60mVp-p and about 3kHz freq (similar to saw shape). I can hear this in speakers in my audio system. On the rest two IC's I doesn't hear anything. Could you advice what can cause this. I've already exchange all the parts and it doesn't help.

The PCB board is already updated according to schematic diagram (the wire layout is old). Below is the diagram and pcb board.

Pawel