Part Number: DRA80M

I looked into Trace32 peripheral registers and didn’t find the VTM_TMPSENSE0_STAT register that was pointed out in spruid7e.pdf at 5.2.6.1.2 (Screen shot below)

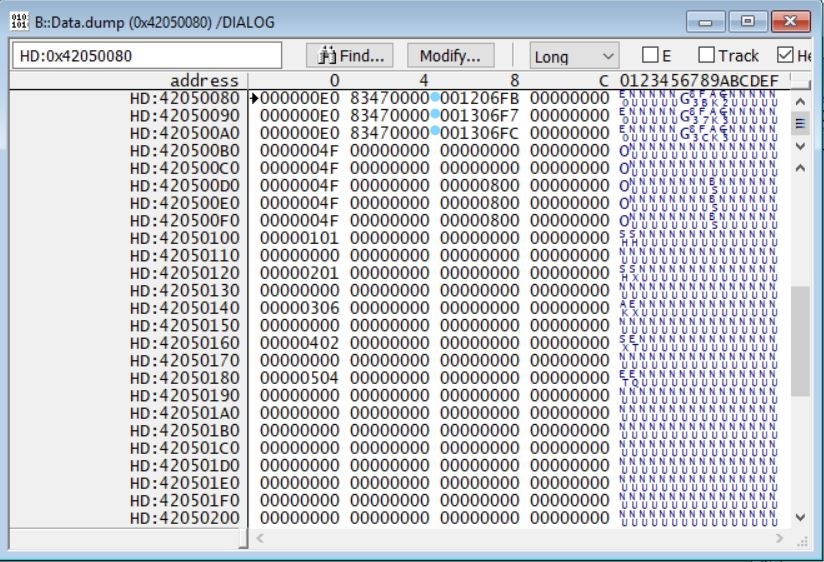

But I could dump the data pointed out at that address 0x4205 0088 (See the attachment TI_Temp.jpg). Right now I see DTEMP value as 0x00 so I’m not sure if that is expected and will change over time?

I would like to know if this is sufficient to monitor or is there any configuration that needs to be done to see the updated Temp values. If so then can TI send us the script file that will help to read out updated Temp value.